Process Safety and

Disaster Prevention / BCP

At the Nippon Soda Group, recognizing that the continuation of safe, stable production activities and the stable supply of products and services is fundamental to our business activities, we promote process safety and disaster prevention activities. Furthermore, we are continuously improving our business continuity plan (BCP) so that we can quickly recover and restart production activities in the event of a disaster or other emergency, while reinforcing our stable supply structure.

- Safety management

We conduct ongoing training programs for operators and share hazardous incident cases across the organization to enhance technical skills and safety awareness, thereby improving employees’ crisis response capabilities.

We also hold regular, practical disaster drills simulating accidents and emergencies as part of our continuous efforts to improve our crisis management system. - Facility maintenance

With the aim of zero equipment-related accidents, we conduct periodic equipment inspections at each manufacturing site in a well-planned manner, and carry out repairs and replacement work in a timely manner with an emphasis on preventive maintenance. When installing new equipment or performing improvement work, our in-house experts perform thorough safety verification. In addition, we undergo regular disaster prevention inspections by external agencies and pursue improvement activities based on the results. - Business continuity plan (BCP)

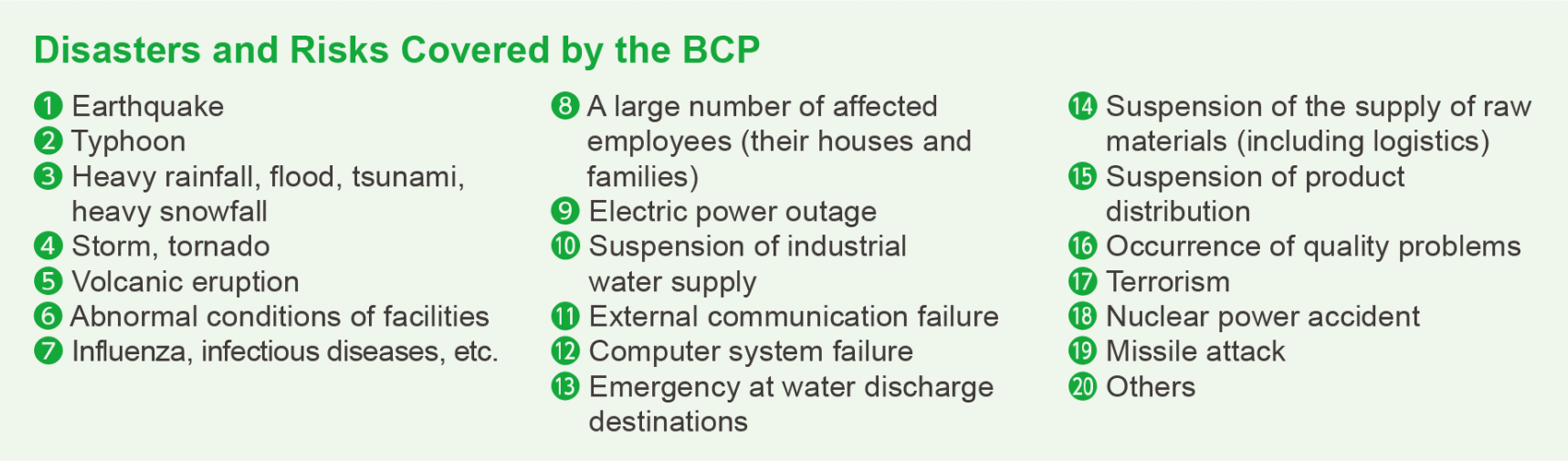

Based on our BCP policy, we take measures in anticipation of major risks, ranging from natural disasters such as major earthquakes and typhoons to outbreaks of infectious diseases and cyberattacks. We also review these measures regularly at the management level to enhance their effectiveness. Clarifying the chain of command and holding information communication drills allows us to strengthen our emergency response capabilities. In addition to ensuring the safety of all stakeholders, including employees and their families, we strive to quickly resume supplying products to our customers, thereby enhancing our business continuity.

FY 2025/3 targets and achievements levels (KPIs)

(Achievement levels ◎:≥ 90% ○:80–90% △:60–80% ×: ≤ 60%) Red text: KPIs

| Nippon Soda Group FY 2025/3 targets |

Nippon Soda (non-consolidated) FY 2025/3 achievements |

Evaluation |

|---|---|---|

| 1. Major accidents at facilities: Zero accidents | ||

| 1) Zero major accidents at facilities |

|

◎ |

| 2) Reduce the risk of major accidents at facilities in line with the business continuity plan (BCP) |

|

◎ |

| 2. Maintenance and improvement of the business continuity plan (BCP) | ||

|

|

◎ |

Process Safety and

Disaster Prevention

Risk Management

| Risk assessment of process safety and disaster prevention | We conduct risk assessments related to safety and disaster prevention for facilities, machines and manufacturing processes. Identified risks are prioritized and, accordingly, measures to ensure the safety of facilities are implemented and inspections are conducted in sequence. |

|---|---|

| Establishment of an emergency risk management system | We give the highest priority to preventing accidents and disasters. On the other hand, to prepare for accidents and disasters, we have established an emergency risk management system and conduct periodic drills and exercises to maintain the system in a sound condition. |

| Standards on Emergency Response | The Standards on Emergency Response have been developed to ensure prompt and appropriate communication, response, and instruction in the event of a disaster or accident, and their effectiveness is reviewed and revised periodically, and confirmed through training. |

Third-party diagnoses of disaster prevention capabilities

Sompo Risk Management Inc. regularly diagnoses the disaster prevention capabilities of Nippon Soda and its manufacturing group companies.

In FY 2025/3, our Research & Innovation Center (Odawara area) and three group company plants underwent diagnoses.

Safety Management

Safety audit to confirm the safety of plants

To ensure the safety of processes in the construction and renovation of facilities, Nippon Soda Group managers and internal experts conduct safety reviews and audits for facilities and operations in terms of safety, work environment, quality and other factors.

Facilities of manufacturing group companies undergo periodic Responsible Care (RC) audits to assess the management conditions of manufacturing facilities and these results have been incorporated into activities to improve process safety and disaster prevention.

Safety audits prior to trial operation by the Head Office

Chiba Plant, December 20, 2024

Safety audits prior to trial operation of manufacturing equipment following Phase Ⅱ of work to increase production capacity for VP polymer solution As a result of document and on-site audits, 25 safety issues were identified. After implementing countermeasures for all of these safety issues, trial operation was complete.

Education and Drills for Disaster Prevention

Nippon Soda provides a variety of process safety and disaster prevention training for employees to acquire the knowledge and skills to ensure their safety. We will continue to promote safety and disaster prevention activities with the aim of further improving them to achieve the target of “no major accidents at facilities.”

Training programs (NTTC: Nisso Technical Training Center)

Each worksite and department conducts continuous education and training in accordance with the CSR action plan. Furthermore, for new employees assigned to our manufacturing sites, we provide manufacturing training programs as a form of new employee training. These programs include experiential education and training related to safety and basic work practices. Moreover, in addition to among new employees, we are also working to improve safety awareness by extending our educational programs to employees in various other positions.

Training courses implemented in FY 2025/3

—: No eligible employees

| Nihongi Plant |

Takaoka Plant |

Mizushima Plant |

Chiba Plant | R&I Center | Group companies |

||

|---|---|---|---|---|---|---|---|

| Training based on length of service | |||||||

| First-year training |

13 | 7 | 1 | 4 | 8 | 9 | |

| Second-year training |

3 | 4 | 2 | - | - | 1 | |

| Third-year training |

3 | 11 | - | 6 | - | 1 | |

| Fifth-year training |

11 | 22 | - | 5 | - | - | |

| Tenth-year training |

2 | 8 | - | 1 | - | - | |

| Fifteenth-year training |

- | 6 | - | - | - | - | |

| Worksite training | - | - | - | - | - | 7 | |

| Partner company training | - | 118 | - | - | - | - | |

| Total | 32 | 176 | 3 | 16 | 8 | 18 | |

Disaster prevention system working in cooperation with local communities

Each Nippon Soda site implements regular disaster drills, which include drills conducted in cooperation with other nearby plants and local governments. These drills are conducted taking into account the environment and other characteristics unique to each region so that they can be applied in real settings.

Comprehensive plant disaster drill

(Chiba Plant, June 11, 2024)

Comprehensive plant disaster drill

(Takaoka Plant, June 12, 2024)

Spring comprehensive plant disaster drill

(Nihongi Plant, June 25, 2024)

Harmful substance (NaOH) leak response drill

(Mizushima Plant, September 5, 2024)

Fire drill

(Takaoka Plant, October 3–24, 2024)

Comprehensive disaster drill

(R&I Center (Odawara), October 18, 2024)

Autumn comprehensive plant disaster drill

(Nihongi Plant, November 14, 2024)

Comprehensive disaster drill

(Chiba Plant/R&I Center (Chiba), February 17, 2025)

Evacuation drill

(Chiba Plant/R&I Center (Chiba), March 17, 2025)

FY 2025/3 Emergency Drills

Business Continuity Plan (BCP)

Basic concept of the BCP

In the event of a natural disaster such as a large-scale earthquake or other crisis that could result in severe damage to Nippon Soda worksites, we consider it our social mission to ensure the safety of local residents, our employees, employees of partner companies, and temporary staff. Based on this concept, the principles of the BCP are defined as follows:

- 1.The highest priority is placed on checking the status and ensuring the safety of Nippon Soda’s own employees, partner company employees and temporary employees and their families, and ensuring the safety of residents in communities where the Company’s business sites are located.

- 2.The consciousness of serving the public and community is shared among all personnel throughout the Company.

- 3.Efforts are focused on protecting the safety of any affected Head Office, plants, research centers, or sales office sites.

- 4.Measures should be taken to establish a system that allows Nippon Soda’s employees, partner company employees and temporary employees who are engaged in ensuring safety and security to act flexibly and at their discretion according to the circumstances.

Continuation of supply of products according to customer needs

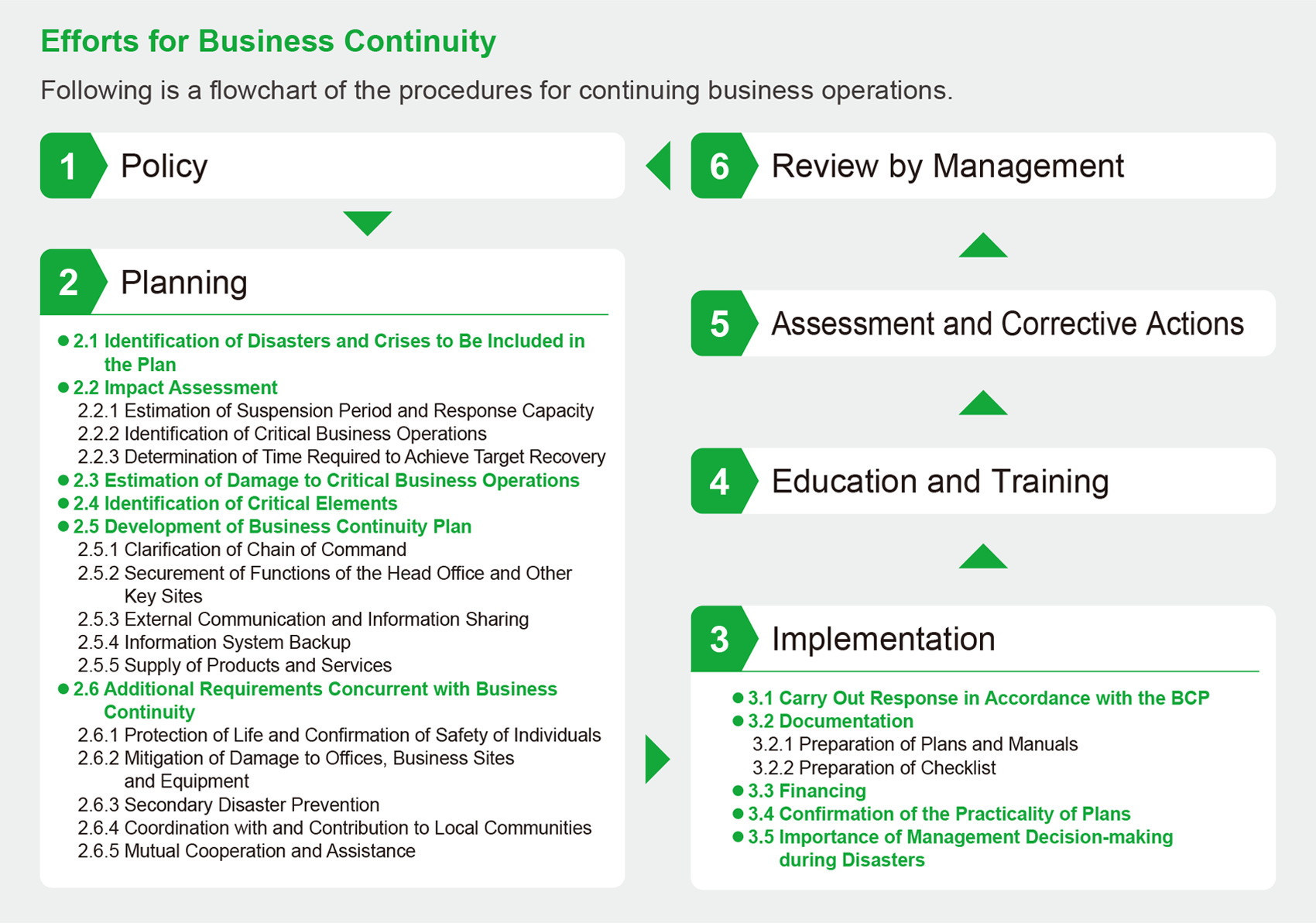

The BCP of Nippon Soda aims to ensure, in the event of a natural disaster or other crisis, safety as well as the supply of products to customers as requested. To achieve this objective, we make continuous improvements using the PDCA cycle.

- 1.Major accidents at facilities: Target: Zero accidents

- 2.Maintenance and improvement of the BCP

Creation of FY 2026/3 version of BCP manual (Ver. 15)