Chemicals and Product Safety

The Nippon Soda Group takes into consideration the potential environmental, safety and health impacts related to the hazards and toxicity of chemical substances and products, complying with laws and ordinances and international standards, while also complying with ordinances based on social demands, so as to earn the trust of customers and society and in turn ensure sustainable business activities.

- Compliance with domestic laws and regulations, international standards, treaties, etc., giving due consideration to the environmental, safety and health impacts related to the hazards and toxicity of chemical substances and products.

- Compliance with social restrictions that are not covered by law to maintain and ensure trust from customers and the general public.

- Specific measures to ensure the safety management of chemical substances, including activities and periodic educational programs regarding chemical and product safety.

FY 2024 targets and achievements levels (KPIs)

(Achievement levels ◎:≥ 90% ○:80-90% △:60-80% ×: ≤ 60%) Red text: KPIs

Safety of Chemicals

Management of Chemical Substances Using a Chemical Substance Management System

Nippon Soda has implemented a chemical substance management system, establishing an efficient management structure for Safety Data Sheets (SDS)* and Yellow Cards. Based on operations using this system, we appropriately update SDSs, Yellow Cards, and product labels to comply with the latest regulations in various countries.

- * Documents that describe information on chemical substances, product names, manufacturers, hazards, handling precautions, emergency response measures, and other safety information.

Regular Training Programs on Chemical Substance Management

We provide employees who handle chemical substances with education on how to comply with Japanese and overseas laws and regulations regarding the management of chemicals.

Product Safety

Actions to Comply with Laws and Regulations

Nippon Soda takes actions to comply with domestic and overseas laws and regulations (including the EU REACH regulations1) and conducts audits of poisonous and deleterious substances at its sales offices.

- 1. REACH (Registration, Evaluation, Authorization and Restriction of Chemicals): European chemicals regulations. European regulations state that businesses that manufacture or import one ton or more of products per year are required to register the substances they handle and submit safety test data, and that substances for which data is not submitted (registered) cannot be sold.

Communication of Safety Information on Chemicals

The Nippon Soda Group participates in GPS / JIPS2 activities. We have prepared safety summary reports on four substances, including caustic soda and hydrochloric acid, which have been registered on the Japan Chemical Industry Association’s BIG Dr chemical substance risk assessment support site.

-

2. GPS (Global Product Strategy): A voluntary industry initiative based on risk assessment and risk management with a global product strategy as the basic concept, taking into account the supply chain

JIPS (Japan Initiative of Product Stewardship): Japan’s version of the ICCA’s3 Product Stewardship (PS) - 3. ICCA (International Council of Chemical Associations)

With a target of compliance with chemical-related laws and ordinances (zero violations), we will reinforce the management of chemical substances through chemical substance management systems, make domestic and overseas SDS / product label revisions, and reinforce examination and management of products containing chemical substances. Moreover, we will offer regular training for new employees on chemical substance management and explanatory sessions on revisions to Japanese and international laws and ordinances.

- 1.Compliance with chemical-related laws and ordinances: Zero violations

- Strengthen chemical substance management (implement domestic and overseas SDS / label system revisions in line with legal reforms, reinforce examinations and management systems for products containing chemical substances)

- Implement regular training on chemical substance management

Consideration in Animal Experiments

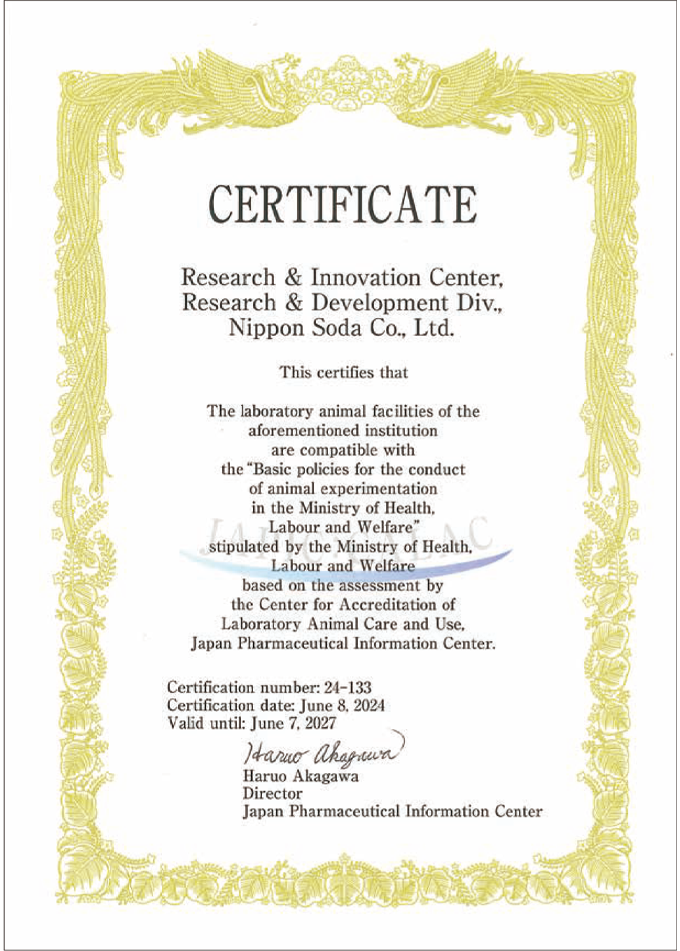

The Research & Innovation Center has formulated its own regulations for animal experimentation and other relevant standards based on the Act on Welfare and Management of Animals, the Ministry of the Environment’s Standards Relating to the Care and Keeping and Reducing Pain of Laboratory Animals, the Ministry of Agriculture, Forestry and Fisheries’ The Basic Policy on Animal Experimentation Performed at Research Institutions, and the Science Council of Japan’s Guidelines for Proper Conduct of Animal Experiments. These activities are validated by an external organization (the Japan Pharmaceutical Information Center4) and the facility was certified in June 2018 as a facility that conducts animal experiments in a proper manner (certification was renewed in June 2024).

- 4. The Japan Pharmaceutical Information Center (JAPIC) has taken on certified businesses from the Japan Health Sciences Foundation, which was disbanded in March 2021.