Promotion of CSR Management

CSR Activities

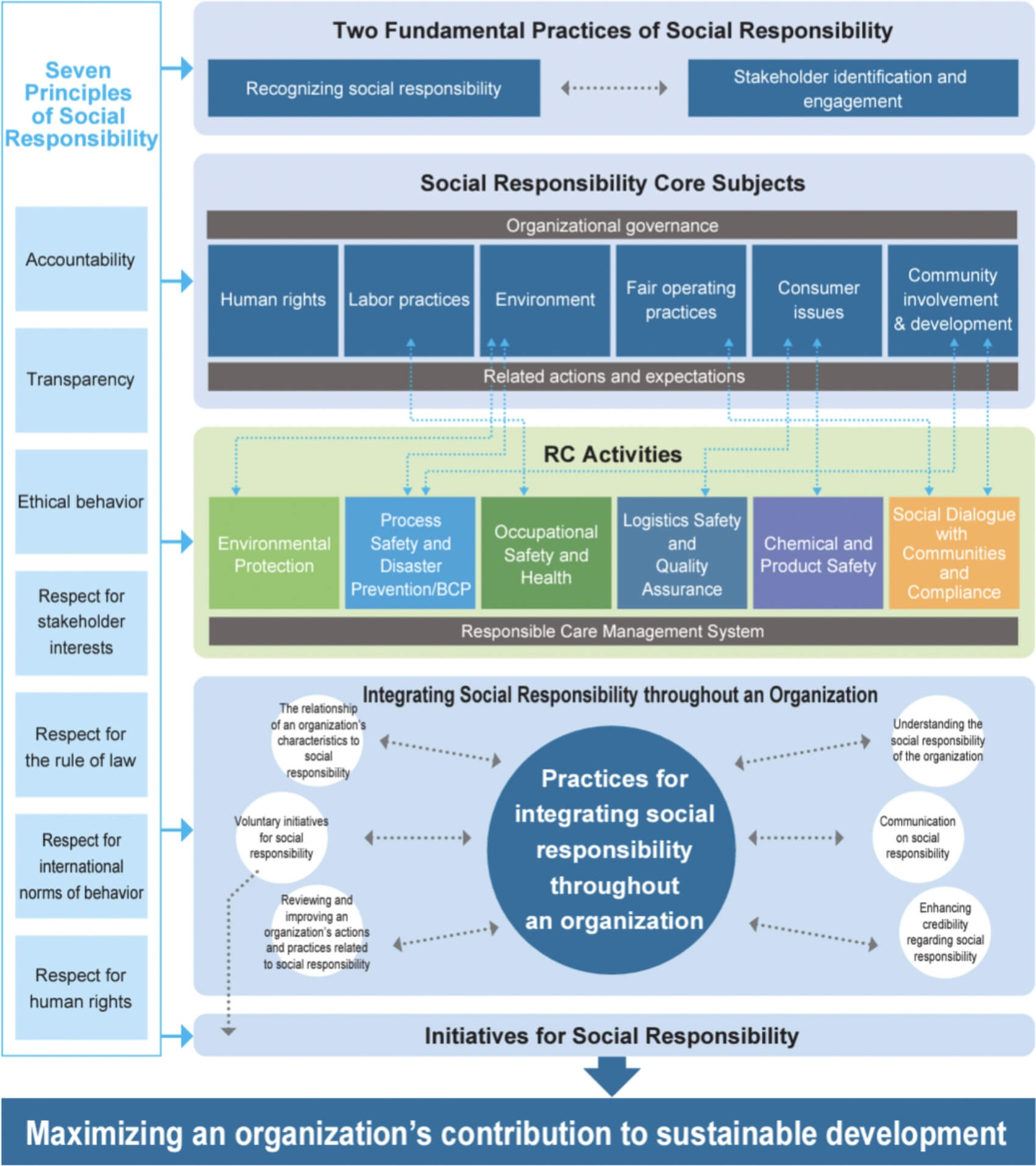

The CSR activities of the Nippon Soda Group include all of the Responsible Care (RC) codes (activity items). All CSR activity items are based on the seven principles of social responsibility described in the ISO 26000 standard and Responsible Care is based on the concepts of “doing what is ethically right” and “implementing proactive measures to reduce risks.” The seven RC codes and the seven core subjects (activity items) of CSR are closely related to each other. The Group integrates these activity items, and on that basis has determined eight policies.

Relationship between CSR (ISO 26000) and RC

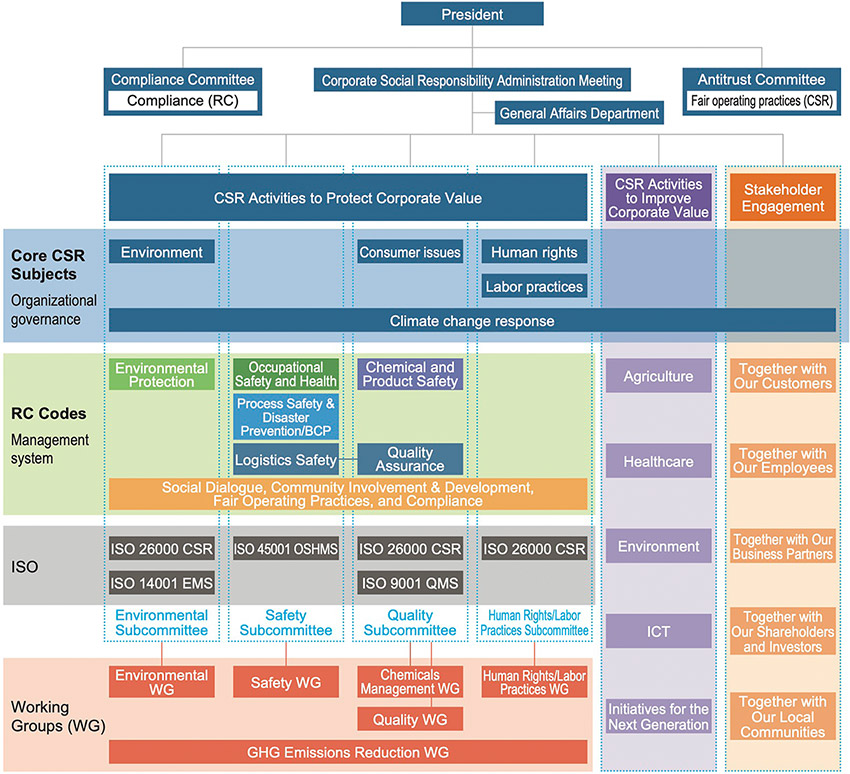

CSR Promotion System

Chaired by the President, the Corporate Social Responsibility (CSR) Administration Meeting is a groupwidedecision-making body that promotes CSR activities, including RC. It sets annual targets to help the PDCA cycle “spiral up” and provides a management-level review of CSR activities. Held twice a year, the CSR Administration Meeting is attended by directors, executive officers and worksite managers.

The following Group companies participate as members in the Corporate Social Responsibility Administration Meeting, subcommittees (Environment, Safety, Quality, Human Rights/Labor Practices), and the GHG Emissions Reduction WG.

| Manufacturing |

Nisso Metallochemical Co., Ltd. Nisso Fine Co., Ltd. Shinfuji Kaseiyaku Co., Ltd. |

|---|---|

| Non-manufacturing |

Nisso Shoji Co., Ltd. Sanwa Soko Co., Ltd. Nisso Engineering Co., Ltd. Nisso Kensetsu Co., Ltd. Nisso Green Co., Ltd. |

| Observers | Nisso Namhae Agro Co., Ltd. (South Korea) |

Ratio of Nippon Soda Group Manufacturing Facilities with ISO Certification*

| ISO14001 | ISO45001 | ISO9001 | |

|---|---|---|---|

| Nippon Soda | 100% | 100% | 100% |

| Nippon Soda Group | 84.6% | 30.8% | 92.3% |

*Current as of March 31, 2024. Percentage of Nippon Soda and Nippon Soda Group (Nippon Soda and its consolidated subsidiaries) whose manufacturing facilities have acquired ISO certification.

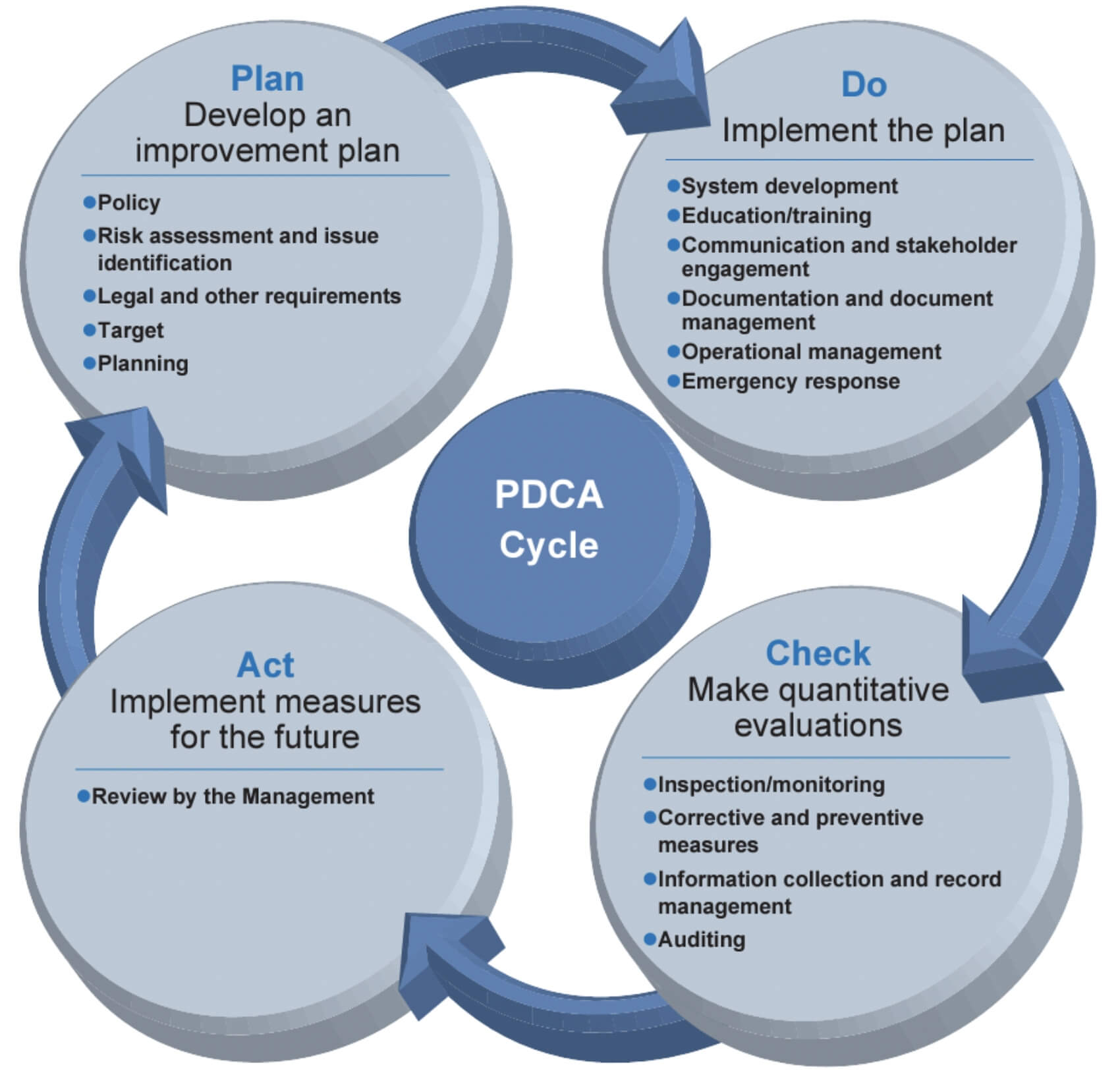

CSR Management System

The management system that promotes the CSR activities of the Nippon Soda Group is designed to “spiral up” the PDCA cycle. Each worksite is required to develop a CSR improvement plan (Plan), implement the developed plan (Do), make quantitative evaluations of both the plan and its implementation (Check), and implement measures based on quantitative evaluation results (Act) in order to continuously improve CSR activities. We also conduct a groupwide audit to assess the appropriateness of activities. We recommend that the PDCA cycle for CSR Activities to Protect Corporate Value be conducted in one year by design. The CSR Promotion Subcommittee holds a meeting to review the progress of the PDCA cycle twice a year. The progress is also reviewed by management twice a year at Corporate Social Responsibility Administration Meetings.

RC Audits

Internal Audits

We collectively refer to internal audits, such as QMS, EMS and OSHMS, that are conducted at each site of Nippon Soda (plants and research centers) as the “RC audit.” To investigate and verify whether the RC audit is conducted appropriately, whether the level of audit quality is appropriate, and other relevant issues, a representative from each site and staff in charge at the Head Office convene once a year to hold an RC Audit, Verification and Review Meeting. The results of internal audits are reviewed at the Corporate Social Responsibility Administration Meeting.

Regular RC Audits

Nippon Soda’s audit team conducts regular (biennial) audits of CSR practices at Group companies.

External Audits/Reviews

All worksites (plants and research centers) and manufacturing Group companies undergo external reviews according to ISO 14001, ISO 9001, and ISO 45001 and diagnosis of disaster prevention capability with emphasis on disaster prevention and occupational safety by an institute specializing in disaster prevention. Based on their results, ongoing improvement efforts are made. We are also subject to appropriate governmental reviews and inspections based on various laws and ordinances, and proactively engage in efforts to address potential areas for improvement.

We proactively welcome audits by customers, who are our stakeholders, and make improvements in response to their feedback. In addition, we also undergo external audits on an as-needed basis.

Special RC Audits

A special audit is conducted, as needed, in the event of a serious non-conformity or other serious problem under an appropriate audit system that can accommodate the situation.

Audits and Reviews Conducted

Audits and Reviews Carried Out at the Nippon Soda Group in FY 2024 (Number of times)

| Site/worksite | Audits received by the Nippon Soda Group | Audits, reviews, and inspections conducted on business partners | |||||

|---|---|---|---|---|---|---|---|

| In-Group audits*¹ | External audits | Total | Contract manufacturer | Raw material manufacturers | Logistics service provider | Waste treatment contractors | |

| Head Office | 6 | 5 | 4 | 4 | 0 | 0 | 0 |

| Nihongi Plant | 13 | 15 | 1 | 0 | 0 | 0 | 1 |

| Takaoka Plant | 25 | 12 | 5 | 0 | 0 | 3 | 2 |

| Mizushima Plant | 7 | 1 | 2 | 0 | 2 | 0 | 0 |

| Chiba Plant | 12 | 6 | 3 | 0 | 0 | 0 | 3 |

| Odawara Research Center | 1 | 0 | 0 | 0 | 0 | 0 | 0 |

| Nisso Metallochemical Co., Ltd. (Group)*² | 16 | 237 | 2 | 0 | 0 | 0 | 2 |

| Nisso Fine Co., Ltd. (Group) | 15 | 18 | 0 | 0 | 0 | 0 | 0 |

| Shinfuji Kaseiyaku Co., Ltd. (Group) |

3 | 10 | 0 | 0 | 0 | 0 | 0 |

| Total | 98 | 304 | 17 | 4 | 2 | 3 | 8 |

1 Includes worksite audits and internal audits.

2 The 237 external audits of Nisso Metallochemical include 220 inspections of the company by a waste treatment contractor.