Message from the President

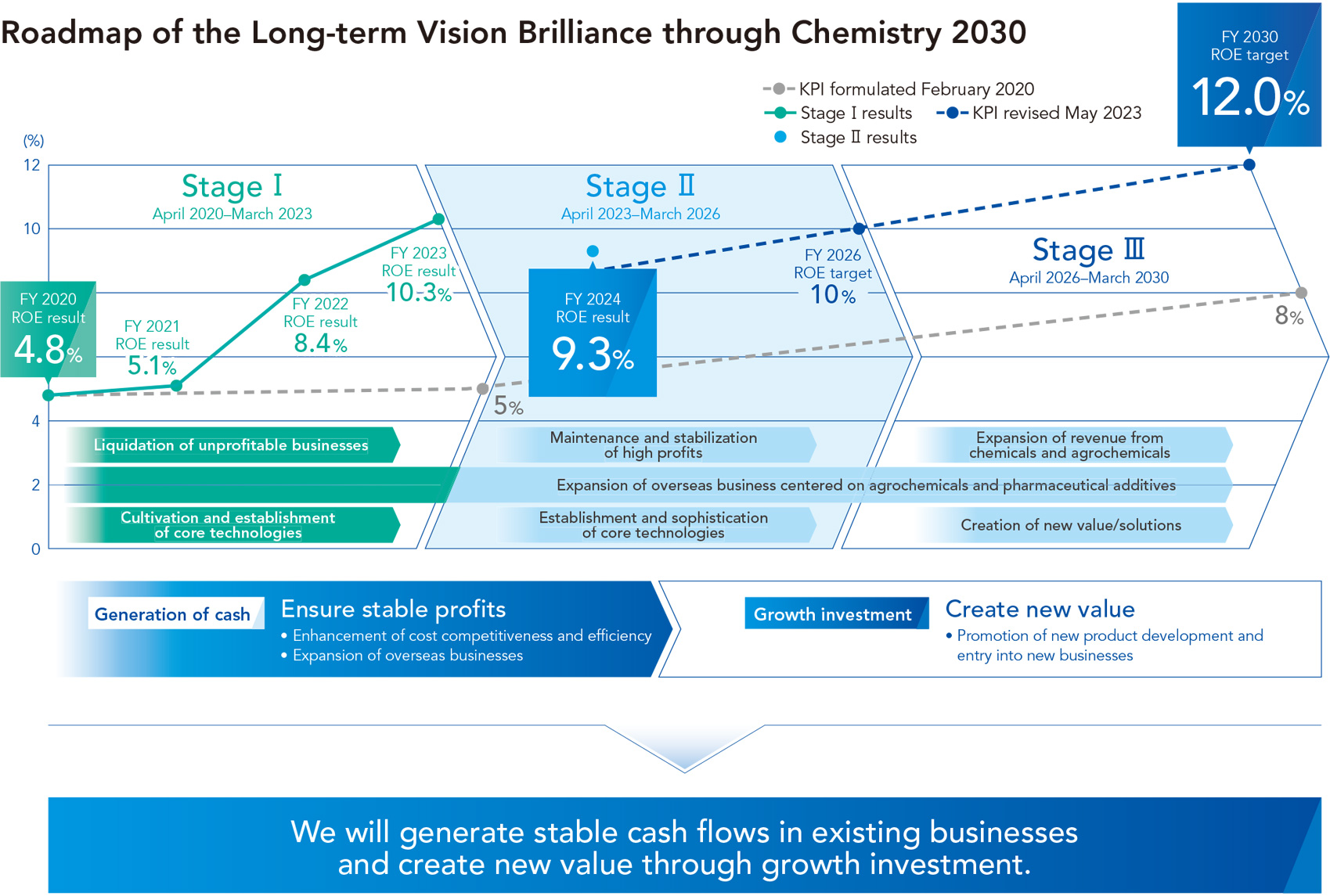

To Contribute to Society and Improve Corporate Value, We Will Promote a Transition to a Highly Efficient Organization by Deepening Our Technologies and Implementing Portfolio Reforms

Eiji Aga Representative Director, PresidentOur mission is to create value through the power of chemistry and to contribute to the resolution of social issues

At the Nippon Soda Group, our mission is to create new value through the power of chemistry and increase corporate value by contributing to society. In this message, I would like to explain the intent behind this mission and introduce some of the Group’s specific initiatives aimed at fulfilling it.

In terms of our contribution to society, I would first like to touch upon the links between the social issues we have identified and our businesses. In 2050, the global population is forecast to exceed 10 billion, which will require vast amounts of food and feed. On the other hand, there is only limited land available for production, and so it will be important to produce food in a more stable and efficient manner than ever before. In this area, the agrochemicals we produce will lead to solid solutions. Moreover, mainly in advanced nations, interest in preventive medicine is leading to a rise in the number of health-conscious people, and as such there is increasing focus on healthcare for both people and pets. Since commencing sales of our pharmaceutical additive NISSO HPC in 1969, we have been improving quality and contributing to greater health and quality of life for people around the world. Elsewhere, the worsening of environmental problems such as global warming and resource depletion requires little introduction. In Japan, average temperatures between June and August 2024 reached record highs, and it was said to be the hottest summer for 126 years since statistical calculations began. At Nippon Soda Group, we are supporting the creation of a sound material-cycle society through technologies to make industrial waste harmless and safe to minimize environmental impact, promote resource recycling, and remove heavy metals. Meanwhile, technological advancements in ICT, and the creation and spread of related services, are progressing at a rapid pace. The chemicals that support these technologies and services must have excellent functionality and reliability, and as such our functional polymers are playing an important role in supporting the IT society.

Chemicals create new value and contribute to social development. While our products and services may operate behind the scenes from society’s perspective, we can make significant contributions to addressing common global challenges. Both our long-term vision and medium-term business plan proclaim “Brilliance through Chemistry.” We have no doubt that we can flourish by creating new value for society using the power of chemistry.

Achieving solutions to social issues in our four target fields and further strengthening our position in global niche domains

In our long-term vision Brilliance through Chemistry 2030, we have identified four materialities (important issues) that will enable us to contribute to the development of a sustainable society and improve our corporate value: Agriculture, Healthcare, Environment, and ICT.

In agriculture, in line with the MIDORI Strategy for Sustainable Food Systems1 in Japan and the Farm to Fork Strategy2 in Europe, the reduction in use of agrochemicals and the switch to low-risk agrochemicals is progressing to ensure the creation of sustainable food systems. Moreover, the market for biostimulants,3 which increase resistance to non-biological stresses such as drought and high-temperature damage, is growing on a global scale. On the other hand, in developing nations where populations are rising, there is a need for highly effective agrochemicals to secure access to food. To cater to these differing circumstances, we are accelerating development of safer, more effective agrochemicals, as well as biopesticides and biostimulants. The three new proprietary agrochemicals we recently released to market are environmentally friendly products that demonstrate highly effective pest control with low doses. As safe and secure agrochemicals, we are currently working on their registration in different countries worldwide. Our mission is to develop and provide agrochemicals that are required by countries and regions across the world. Making full use of our technologies, we will continue to contribute to sustainable food security.

In healthcare field, the global pharmaceuticals market is expected to grow over the medium to long term due to growing demand in emerging nations such as India and China, and the development of new technologies. Demand for our pharmaceutical additive NISSO HPC, which is used as a binder to form tablets, is growing on a global scale due to its adoption in new pharmaceuticals. To respond to this soaring demand, we are currently moving forward with construction work to reinforce our production capacity by 50%, and we are putting systems in place to ensure we can begin full-scale operations upon the work’s completion in the first half of FY 2027. While previously low-molecular-weight medicines were the mainstream, recently there has been a rise in protein and nucleic acid medicines. New formulation technologies are essential to ensure that these new active ingredients are thoroughly absorbed by the body. At Nippon Soda, we are currently engaged in open innovation to develop a new formulation technology using nanoparticulation technology, and personally I am very much looking forward to being able to announce our achievements. In the future, the increase in number of senior citizens is expected to lead to a rise in number of daily medicines to counter lifestyle-related diseases. The development of new formulation technologies has the potential to reduce the number of tablets that must be taken in a single sitting from ten to just one or two, for example. By refining the formulation technologies we have been developing through NISSO HPC for the creation of efficient drug delivery systems, we will contribute to the improvement of people’s health and quality of life.

In the environment field, we are providing various environmental solutions using the different technologies we have accumulated throughout our long history. For example, we have fluorocarbon treatment technologies to make industrial waste harmless and safe, resource recycling technologies for zinc and sulfuric acid, and water treatment technologies to disinfect and sterilize water. With changes in the social environment, there is expected to be an increase in difficult-to-treat waste and further requirements for lower environmental impact. Applying the expertise and experience we have gained to date, we will contribute to realizing sound resource recycling with the power of chemistry.

In ICT field, sales of VP-POLYMER, a KrF photoresist material for semiconductors, NISSO-PB, a resin additive for electronic materials, and other functional polymers have increased since the beginning of FY 2025. This increase can be attributed to rapid progress with electrification and automated driving in the automotive industry, with even low-priced compact cars being equipped with driving support devices such as adaptive cruise control. This growth in number of semiconductors used in vehicles and the increase in production of 3D-NAND flash memories is driving demand for VP-POLYMER. To ensure stable supplies in this environment, in the second half of 2024 we will complete work to double our current production capacity. In Japan, the decline in working populations will undoubtedly lead to further corporate use of AI. Already, we are seeing an increase in demand for NISSO-PB for use in AI servers.

- 1. A strategy put together by the Ministry of Agriculture, Forestry and Fisheries to achieve both productivity improvement and sustainability through innovation in the food industry and the agriculture, forestry, and fishery industries. The Act to Promote Environmental Burden Reduction Activities for Establishment of Environmentally Harmonized Food System was implemented in July 2022

- 2. A strategy formulated by the European Commission in 2020 to build sustainable food systems. The aim is to create fair and healthy food systems through the combined efforts of farmers, companies, consumers, and the natural environment

- 3. Agricultural materials made from various substances and microorganisms that promote better physiological conditions in plants and soil

Formulating a research and technology strategy and proactively investing in the enhancement of in-house technologies and co-creation with external organizations

Our long-term vision is not simply an extension of our existing businesses. Rather, to create new core businesses for 2030 onwards, we will reinforce our research and development capabilities and proactively engage in open innovation and form alliances.

In April 2021, we integrated the Odawara Research Center and the Chiba Research Center, which previously conducted R&D in different fields, to form the Research & Innovation Center, to promote the fusion of knowledge and fusion of technologies through greater communication. Moreover, in April 2024, we have integrated the production technology research departments from four business sites to form the Production Technology Center, reorganizing structures to promote interaction among our technical personnel. There can be no doubt that our core domains from 2030 onwards will be Chemical Materials and the Agri Business. We have therefore formulated the research and technology strategy Brilliance through Chemistry 2030 to establish and advance our core technologies, respond to social changes and technological advancements, and ensure continuous innovation. By the end of 2030, the final year of our long-term vision, our plan is to create new businesses that become pillars for further growth, and we have identified three target domains in which to set up these new businesses: Food, Healthcare, and Advanced Materials. While our chemical technologies can cater to various social needs, offering solutions to a broad range of issues is not the optimal approach for us. Rather, we believe that for us, it is important to target niche markets that align with the scale and strengths of the Group.

As measures to establish and advance our core technologies, we are working to reinforce our platform technologies and establish technologies to strengthen as a matter of priority. We have defined our platform technologies as agrochemical creation technologies, bioresource utilization technologies, and functional material creation technologies, and will work on the strengthening and development of these areas using in-house resources and technologies. To do so, using information on our in-house technologies, we will aim to create new value by combining in-house technologies or fusing them with external expertise. Elsewhere, we have set cultivation technologies, peptide application technologies, organic metal application technologies, flow synthesis technologies, and AI/MI (materials informatics4) technologies as those to strengthen as a matter of priority. Here, by proactively introducing external technologies, our aim is to acquire and reinforce new technologies. Our engineers take great pride in their own technologies. Perhaps because of this, our research and development to date has relied on internal capabilities alone. However, with this approach, we will not be able to keep up with technological trends and will ultimately be left behind. As such, we are currently accelerating collaborations with startups, universities, and other research institutions. Combining the attractive technologies of each of these partners with the synthesis technologies we have accumulated through the development of agrochemicals and materials, our scaling expertise, and various evaluation technologies will facilitate the creation of new businesses.

Our research and development using external technologies is progressing smoothly. With flow synthesis technologies, for example, we are working with the University of Tokyo and a pharmaceutical company to develop and acquire a continuous flow technology. Mechanical components for cars, for example, are mainly produced using continuous flow methods, but pharmaceuticals, agrochemicals, functional chemicals, and other chemical products are made using the batch production method.5 While this batch method is suited to high-mix, low-volume production, its disadvantages includes the need for significant manpower and large volumes of waste. With the continuous flow method, on the other hand, everything from the input of raw materials to the removal of the final product is done in a single, continuous operation. As such, the method boasts excellent energy efficiency and safety and generates little waste. That said, previously there were significant technological challenges with the use of the continuous flow method for pharmaceuticals and other chemicals due to their complex structures, but the University of Tokyo discovered a solution. Introducing the continuous flow method can make equipment, heat sources, and other utilities more compact, improve efficiency, reduce the required manpower, cut environmental impact, and reduce raw material costs. Our Research & Innovation Center and Production Technology Center have identified targets and are currently moving forward with research on improving efficiency. Based on the results of this research, we will examine use of the continuous flow method in future new products.

In advanced materials, we are entering the final stage of joint development with Kyulux, Inc. related to organic electroluminescence materials. Using our expertise in organic synthesis and our scaling technologies, this initiative was launched to support the commercialization of Kyulux, Inc.’s high-performance TADF6 material. Since April 2024, the former manager of our New Business Planning & Development Department has been assigned near Kyulux Inc., aiming for early mass-production.

We are also accelerating open innovation in other ways. For example, we are participating in collaborative material development projects, including investments in material tech startups, and research and development projects such as the conversion of carbon dioxide into valuable substances based on the solid solution alloy nanoparticle technology cultivated through joint research with Kyoto University.

- 4. A field of study for discovering new materials through large amounts of data by applying informatics methods, such as statistical analysis

- 5. A production method in which each individual process, including the input of raw materials, reaction, suspension, and the removal of the final product, is conducted in repeat cycles

- 6. Thermally Activated Delayed Fluorescence: TADF materials are expected to be the third generation of organic electroluminescence materials for the luminous layer

Aiming for sustainable corporate development through portfolio reforms, DX promotion, and human capital management

We understand that it is essential to thoroughly improve management efficiency and implement flexible business portfolio reforms if we are to achieve our long-term vision and, beyond that, ensure sustainable corporate development. For our business portfolio reforms, in addition to expanding our high-added-value businesses, we have liquidated our unprofitable businesses in response to changes in the business environment. We will continue to push forward with portfolio reviews, and alongside each department we are carefully examining the profitability of each product and discussing future reviews and measures. Meanwhile, the liquidation of unprofitable businesses is not as simple as just withdrawing from the business. For example, in the manufacture of chemicals, waste such as gases that affect the environment is generated. While of course we use incinerators and other means to render this waste harmless, if we stop manufacturing several unprofitable products, the remaining products must bear the indirect fixed costs for incineration, which worsens the profitability of these products. As a result, the profitability for these other products deteriorates. We are therefore engaging in various discussions to find an optimal solution, such as the introduction of more compact and efficient incinerators.

Meanwhile, as working populations continue to decline, DX promotion will be essential to achieving greater production efficiency, advancing manufacturing and research technologies, and improving efficiency in various other operations. As part of our research and technology strategy, we have identified AI/MI as technologies to strengthen as a matter of priority. Five years ago we set up the AI Working Group, mainly comprising junior employees, tasking its members with freely exploring what can be done with AI and promoting DX through a bottom-up approach. Our development of AI-proficient personnel is progressing smoothly, and a project led by junior employees to develop a generative-AI-based in-house app has proceeded at remarkable speed, and the app has already been patented. Currently, we are developing various tools. In the future, using generative AI, we will aim to match the Group’s technological information with future needs and reflect the results into our business plans.

Another important theme for the future is human capital management. At Nippon Soda, we have set up the Free Talk Square and the President’s Announcement to boost communication between management and employees. Free Talk Square activities involve directors exchanging opinions with employees from each worksite. The President’s Announcement, meanwhile, is something that has been continued through generations of presidents, and involves me visiting each worksite twice a year to explain our management conditions and measures to achieve our long-term vision in an easy-to-understand manner using different charts and diagrams. Directly communicating what needs to be done during certain periods is incredibly important, and I have a real sense that employees are beginning to understand the significance of our long-term vision, our future course of action, and our reasons for profit-focused management. I also regularly communicate the strong need for safety and compliance to take precedence over the achievement of production plans. As a chemical manufacturer we handle dangerous substances at our plants. No matter how hard we work to achieve results that exceed our targets, a single major accident or scandal can lead to the suspension of operations and put the company’s survival at risk. We are using specific examples to explain the importance of appropriate action and employees are responding in a sensitive manner. On the other hand, although I have the opportunity to meet with Group company presidents and key officers through the President’s Announcement and other regular meetings, one issue is the lack of opportunities in place for me to speak with Group company employees.

In FY 2025, we are focusing on personnel system reforms including in areas such as working environments, employee treatment, and employee welfare programs. According to one recruitment website, “Nippon Soda has a seniority-based system, and people who are not competent enough are becoming managers.” While this is the opinion from a single individual who left the Company, I interpret it as a sign of low satisfaction with our personnel systems. Realizing the difficulty in fundamental reforms, including for evaluation systems, using only internal capabilities, we have solicited the help of external consultants for inspections and advice on system reforms. In FY 2026, our plan is to implement new personnel systems that are more in line with changing times, ensuring that those who work hard are recognized accordingly and that they are quickly promoted. Alongside these evaluation systems, another hot topic in discussions we hold with junior employees is job transfers. With our withdrawal from unprofitable businesses and the decline in working populations, to ensure optimal personnel deployment it is impossible not to transfer our employees on occasion. However, to respond to the opinions of employees and their families, we are currently examining ways to reduce the number of job transfers. We are also working to create workplaces where diverse human resources can work in safety and with peace of mind through the creation of systems that enable employees to play active roles regardless of their gender, age, nationality, ability or disability, or any other attribute.

Valuing tradition while driving reforms to continue as a Group that is essential to society for the next 100 years

In FY 2024, the first year of Stage II of our medium-term business plan, the expansion of high-added-value businesses and work to increase production capacity for our growth driver products progressed as planned. However, during the 2024 Noto Peninsula earthquake in January 2024, the Takaoka Plant in Toyama Prefecture suffered major damage which led to repair costs and a loss in sales opportunities. Unfortunately, the impact from this incident has continued into FY 2025. Meanwhile, the Mizushima Plant in Okayama Prefecture is the only factory in Japan producing sodium cyanide and potassium cyanide. However, with a drastic drop in production of key raw materials by our neighboring supplier, it has become impossible to source the raw materials required for stable plant operations. As such, we made the agonizing decision to close the Mizushima Plant in FY 2026. Despite these two unforeseen occurrences in 2024, we will strive to make steady forward progress to ensure we achieve the KPIs in Stage II as promised to our shareholders and investors. Moreover, aiming to enhance our financial efficiency, we will continue to optimize our assets, including through the reduction of cross-held shares.

Nippon Soda was founded in 1920 and boasts more than a century of history. In addition to responding to the expectations and trust placed in us by customers, shareholders, investors, business partners, employees, local communities, and other stakeholders, we have developed our businesses to contribute to society. Ahead of the next 100 years, while valuing our traditions we will strive for innovation with a constant eye on the future, and do everything we can to continue to develop as a Group that is required and trusted by society. Today, sustainability is a key theme for global society, but at Nippon Soda we have engaged in Responsible Care activities for many years and a CSR-focused approach is firmly rooted in our business activities. Moving forward, using chemistry to provide various products, we will continue to offer solutions to challenges facing global society over the long term. I look forward to your continued support.

Eiji Aga Representative Director, President