Logistics Safety and

Quality Assurance

At the Nippon Soda Group, to ensure the safe and stable delivery of products to our customers, we work to minimize distribution risks and prevent any logistics accidents in advance. Furthermore, by providing environments in which customers can use our high-quality products and services in a safe manner and with peace of mind, we are striving to improve customer satisfaction.

- Logistics safety

We endeavor to proactively prevent logistics accidents by reducing hazards and toxicity associated with product transportation, as well as the risk of accidents during transportation. In particular, we do our utmost to ensure the safety of our customers, those involved in the distribution process and local residents, and to protect the environment by taking thorough measures to prevent major accidents involving environmental pollution and health hazards to humans caused by chemical leaks or spills. - Quality assurance

We contribute to customer satisfaction by offering high-quality, eco-friendly products that minimize the use of hazardous substances, and providing information that helps customers use our products safely, reliably, and in a stable manner.

FY 2025/3 targets and achievements levels (KPIs)

(Achievement levels ◎:≥ 90% ○:80-90% △:60-80% ×: ≤ 60%) Red text: KPIs

- * After identifying quality-related risks, we classify them based on their severity, frequency, detectability, and other factors. For particularly severe risks (rank A and B), we implement focused reduction activities to reduce the number of product-related complaints.

Logistics Safety

Measures to Ensure Safe Transportation of Dangerous Goods

Logistics risk assessment

The Nippon Soda Group takes measures to reduce risks from various perspectives to prevent accidents involving workers and products caused by traffic accidents during forklift loading, unloading and trans-shipment of products, as well as during truck transportation.

Promotion of Yellow Card1 and Container Yellow Card (product labels)2

The Nippon Soda Group promotes the use of Yellow Cards and Container Yellow Cards. We continuously revise product labels in a timely manner to reflect the latest information, including legal revisions, ensuring GHS3 compliance and the use of appropriate pictograms. These measures enable us to respond quickly and prevent damage from spreading in the event of a disaster.

- 1. Yellow Card: An emergency information card with information about procedures that drivers, fire and police personnel, and other concerned parties should take in the event of a spill, fire, explosion or other incidents during transportation. It also contains emergency contacts. The issuance and carrying of Yellow Cards is required by the Poisonous and Deleterious Substances Control Law and other laws.

- 2. Container Yellow Card: A label that is affixed to containers with the United Nations number and guide number from the Emergency Response Guidebook.

- 3. Globally Harmonized System of Classification and Labelling of Chemicals (GHS): A system for the international standardization of classification and labeling of chemicals, which was agreed upon by the United Nations Economic and Social Council. It is a system of international hazard classification standards and labeling methods (product labeling and SDS) for chemical hazards.

Logistics Safety in Value Chains

Proposals for improvement of customers’ facilities

In the event that there is a problem with the safety of the transport company or the customer’s workers at the customer’s product receiving facility, or if there is a potential risk of foreign matter entering the facility or spills, the Nippon Soda Group makes proposals for improvement and works to prevent accidents and disasters.

Quality Assurance

Efforts to Ensure Quality Management

Quality risk assessment

Nippon Soda actively engages in quality risk assessment with the goal of preventing the occurrence of productrelated complaints and the recurrence of such complaints. We make continuous efforts to identify qualityrelated risks from each manufacturing site and reduce the risks, especially the high-risk A and B ranks.

Efforts to Achieve Zero Product-related Complaints

To eliminate product-related complaints, we conduct quality risk assessments to identify and reduce risks. We are also working to reduce product-related complaints due to human error through human error prevention training for employees.

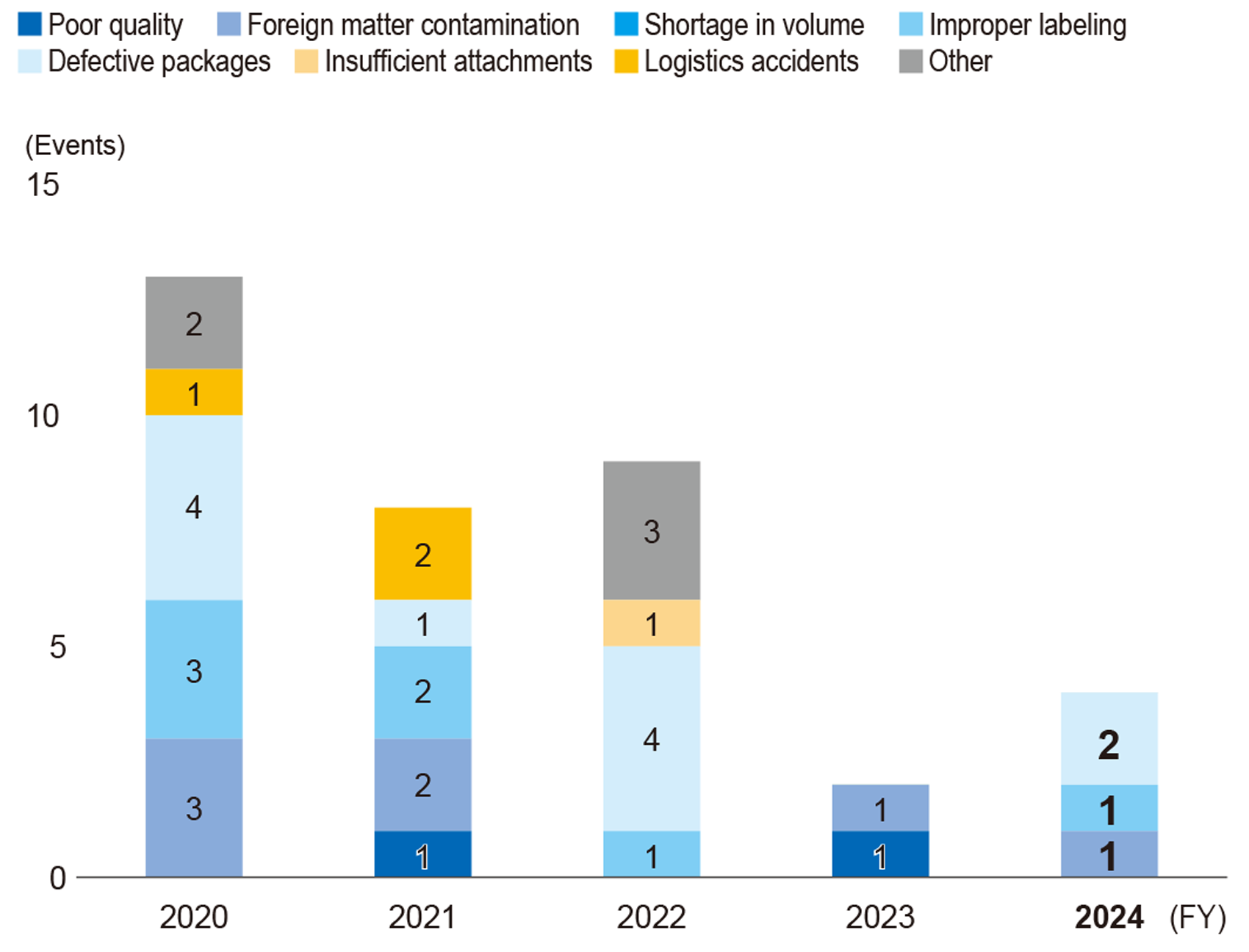

Number of product-related complaints

- 1.Logistics accidents

- 1-1.Major logistics accidents: Zero occurrences (leaks, misdeliveries, incorrect shipments, losses, vehicle-related accidents (involving physical injury))

- 1-2.Transportation-related accidents: 20% reduction year on year

- 1-3.Storage and cargo-handling-related accidents: 20% reduction year on year

- Continue to provide training to shipping companies.

- 2.Product-related complaints: No more than 4 incidents (20% reduction compared to average between FY 2020/3–2022/3 [10 incidents])

- Reduce rank A and B risks uncovered in quality risk assessments (30% reduction of eligible risk incidents)