Occupational Safety and Health

At the Nippon Soda Group, we believe that it is people who enhance the competitive advantage of the Company. We also believe that people are the most important management resource in bringing about sustainable growth. To ensure employee motivation and create workplaces that are full of energy, we strive to prevent occupational accidents and health issues, promoting health and productivity management so that both employees and their families can maintain and improve their physical and mental health.

- Introduction of an Occupational Safety and Health Management System (OSHMS), and implementation of risk assessments. Acquisition of ISO 45001 certification.

- Continuous implementation of PDCA (Plan-Do-Check-Act) to ensure safe and healthy workplaces with the aim of achieving the goal of zero occupational accidents.

- Provision of health guidance based on medical examination results and implementation of measures to reduce incidents of personal injury or illness to help employees maintain and improve their health.

- As a mental healthcare service, we perform stress tests and provide consultation services by qualified mental health specialists. We have established and are operating a system that allows us to take appropriate action.

FY 2024 targets and achievements levels (KPIs)

(Achievement levels ◎:≥ 90% ○:80-90% △:60-80% ×: ≤ 60%) Red text: KPIs

Implementation of Risk Assessment

We are systematically improving the achievement and performance of the targets we have set through the PDCA cycle set out in OSHMS. To integrate OSHMS and Responsible Care (RC activities) effectively, we also emphasize OSHMS risk assessment. Each office (plant or research center) periodically identifies and assesses occupational accident risks and, if they are not acceptable, takes measures to minimize them.

Efforts to Prevent Occupational Accidents

Establishment of Safety and Health Committees

In line with Article 19 of the Industrial Safety and Health Act, at Nippon Soda we have established a Safety and Health Committees at each of our worksites. The committees meet once a month, aiming to prevent occupational accidents and health hazards, and maintain and promote employee health. In addition, we have also established a Central Safety and Health Committee, chaired by the Responsible Care Management Department’s general manager. It comprises safety and health supervisors from each department and worksite, and meets in principle twice a year. In addition to the views of management, the central committee incorporates wide-ranging opinions from labor unions and health insurance associations in order to improve working environments.

Activities to reduce occupational accident risks

Mainly in accordance with activity plans set forth in OSHMS, we are reducing risks through the elimination of near-miss incidents and by drawing on examples of disasters at other worksites and other companies. When new plants are constructed or when plants are expanded, we require safety reviews and audits to reduce accident risk to an acceptable level before starting test operations.

Efforts to prevent human error by workers

The 5Ss—seiri (sorting), seiton (setting-in-order), seiso (shining), seiketsu (standardizing) and shitsuke (sustaining the discipline)—and the four Safety Cycles (KY* before starting operation → Pointing and vocalizing during operation → Mutually directing attention during operation → Identifying hiyari-hatto (near miss) accidents after operation) are the concepts that form the basis of safety activities for the Nippon Soda Group. In addition, senior management at each business site takes the initiative in promoting safety awareness among employees so that safety activities are improved through the continuous application of the PDCA cycle.

- * A combination of the first letters of two Japanese words, K for kiken (danger) and Y for yochi (prediction). The KY system is designed to identify latent risks associated with work and take preventive measures before they occur.

Third-party occupational health and safety survey

At Nippon Soda, we undergo occupational health and safety surveys by Sompo Risk Management Inc. (The Chiba Plant was inspected on December 8, 2023.)

Number of consecutive days (years) without an accident resulting in absence from work, and number of accidents resulting in absence from work of employees

| Worksite | Number of consecutive days (years) without an accident resulting in absence from work1 | Number of accidents resulting in absence from work2 |

|---|---|---|

| Head Office | 479 days (1 year) | 0 |

| Nihongi Plant | 467 days (1 year) | 0 |

| Takaoka Plant | 507 days (1 year) | 0 |

| Mizushima Plant | 11,469 days (31 years) | 0 |

| Chiba Plant | 7,174 days (19 years) | 0 |

| Odawara Research Center | 8,563 days (23 years) | 0 |

| Aizu Plant, Nisso Metallochemical Co., Ltd. | 607 days (1 year) | 0 |

| Chiba Plant, Nisso Metallochemical Co., Ltd. | 13,573 days (37 years) | 0 |

| Koriyama Plant, Nisso Fine Co., Ltd. | 164 days (0 years) | 2 |

| Isohara Plant, Nisso Fine Co., Ltd. | 5 days (0 years) | 1 |

| Onahama Plant, Nisso Fine Co., Ltd. | 2,111 days (6 years) | 0 |

| Shinfuji Kaseiyaku Co., Ltd. | 144 days (0 years) | 2 |

| Nisso Shoji Co., Ltd. | 7,611 days (20 years) | 0 |

| Sanwa Soko Co., Ltd. | 1,395 days (3 years) | 0 |

| Sanso Unyu Co., Ltd. | 842 days (2 years) | 0 |

| Nisso Engineering Co., Ltd. | 6,741 days (18 years) | 0 |

| Nisso Kensetsu Co., Ltd. | 428 days (1 year) | 0 |

| Nisso Green Co., Ltd. | 8,767 days (24 years) | 0 |

- 1. As of 1 April 2024 2. Data collected from FY 2024 (April 2023–March 2024)

Number of accidents resulting in absence from work among employees of Nippon Soda and partner companies

| FY 2019 | FY 2020 | FY 2021 | FY 2022 | FY 2023 | FY 2024 | |

|---|---|---|---|---|---|---|

| Nippon Soda | 0 | 1 | 4 | 0 | 5 | 0 |

| Nippon Soda’s partner companies | 3 | 0 | 3 | 0 | 2 | 3 |

| Group companies | 5 | 1 | 2 | 6 | 3 | 5 |

| Group companies’ partner companies | 2 | 3 | 2 | 1 | 2 | 1 |

- Note: Data collected from April 1 to March 31 of each year.

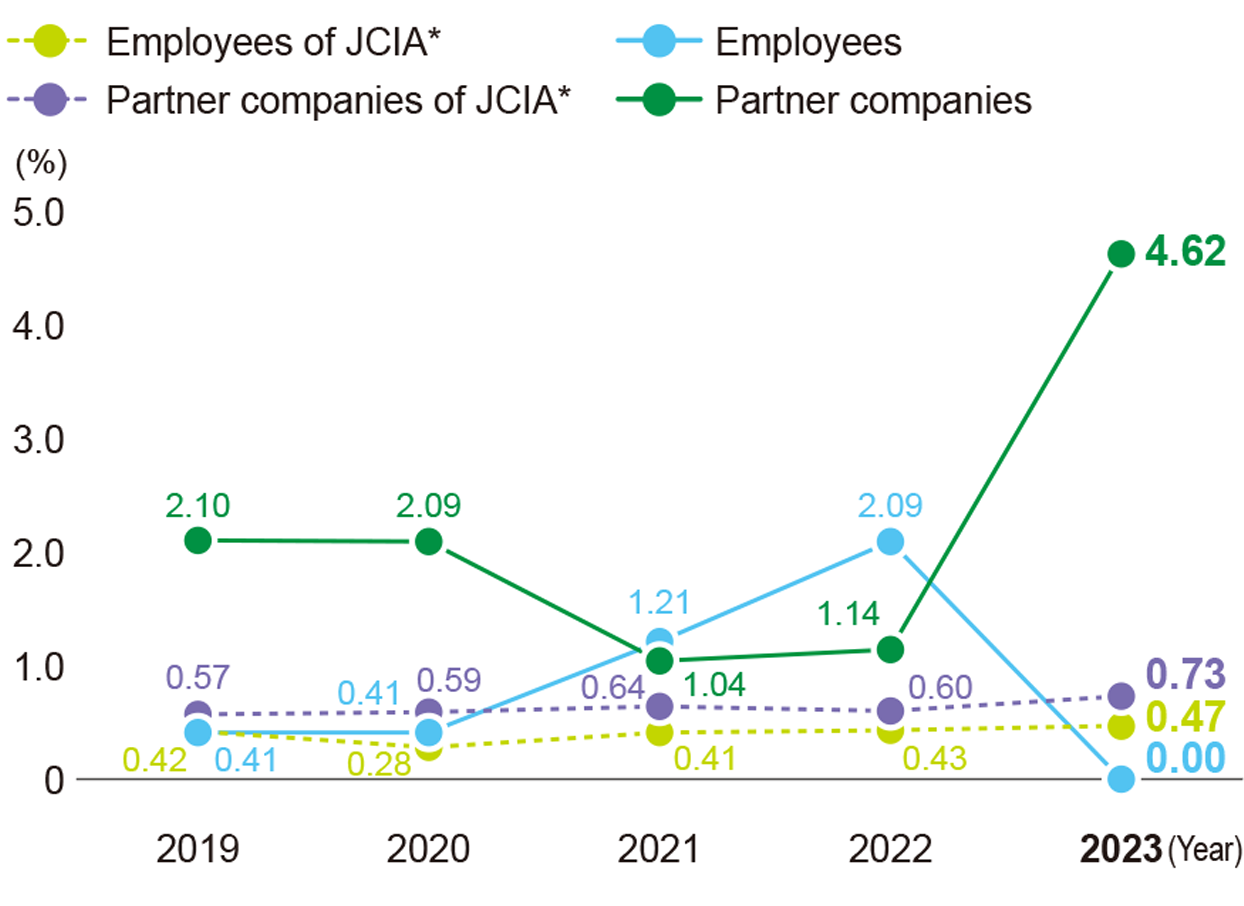

Occupational accident frequency rate

- * JCIA stands for Japan Chemical Industry Association.

Occupational accident frequency rate: Casualties caused by occupational accidents ÷ Total actual working hours × 1,000,000

Data collected from January 1 to December 31 of each year.

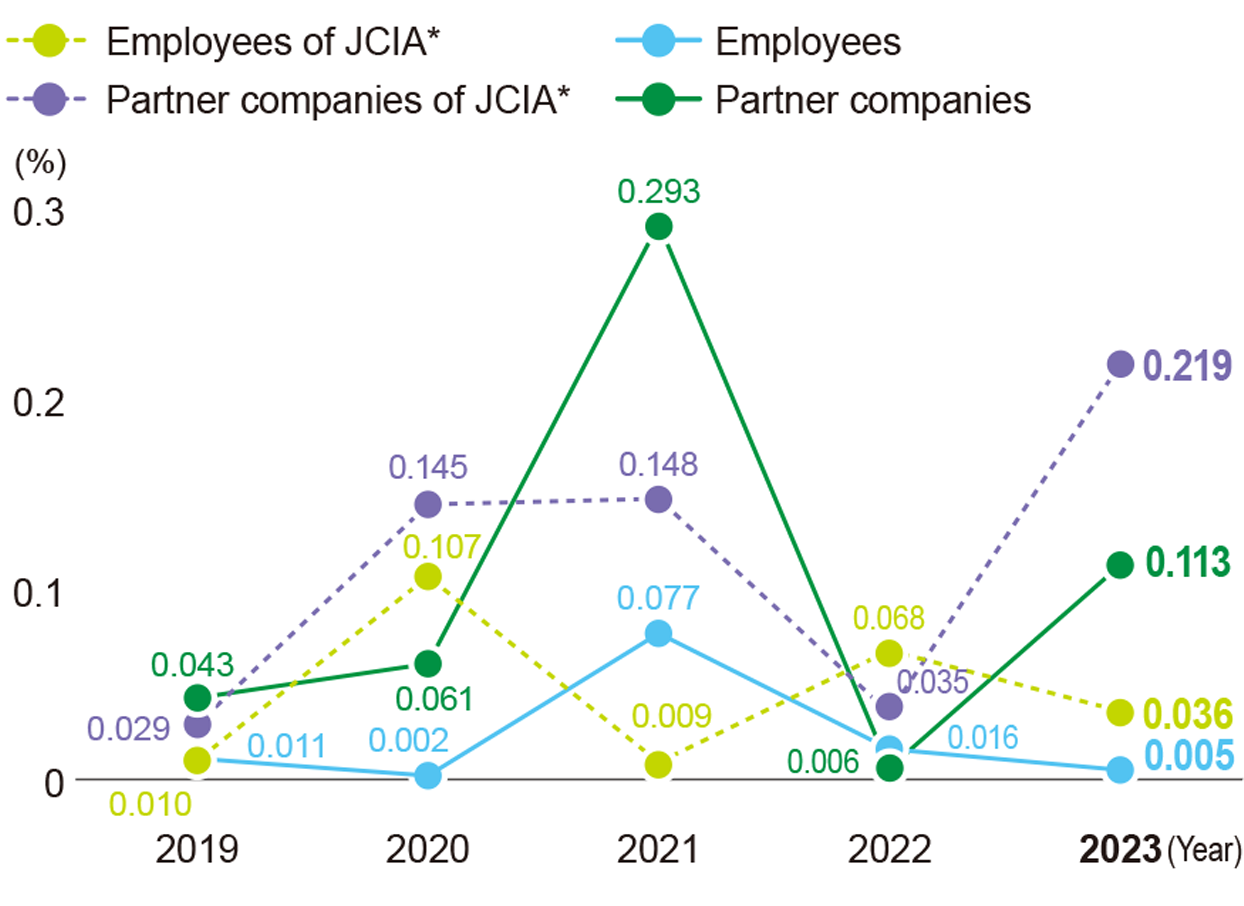

Severity rate of occupational accidents

Severity rate of occupational accidents: Total working days lost ÷ Total actual working hours × 1,000

Data collected from January 1 to December 31 of each year.

Severity rate of occupational accidents: Total working days lost ÷ Total actual working hours × 1,000

Data collected from January 1 to December 31 of each year.

Number of occupational accidents within the above period that led to an employee’s death (number of deceased): 0 (0)

Number of occupational accidents at partner companies within the above period that led to an employee’s death (number of deceased): 0 (0)

Proactive Health Management for Workers

Health and Productivity Management

In March 2024, Nippon Soda was recognized in the 2024 Certified Health & Productivity Management Organization Recognition Program (White 500) for the seventh year in a row under the recognition program jointly undertaken by the Ministry of Economy, Trade and Industry and the Nippon Kenko Kaigi. This program recognizes large enterprises that promote outstanding health and productivity management. Recognition is based on an assessment of the Company’s effectiveness in addressing health-related issues in local communities or their health promotion activities as promoted by the Nippon Kenko Kaigi.

Recognizing the importance of health maintenance and improvement in business management, Nippon Soda, in cooperation with the Nisso Health Insurance Association and the labor union, promotes efforts geared toward supporting physical and mental health. We support employees and their families in their health management and proactively promote health and productivity management so that we can provide better value to the public through business activities conducted by healthy and lively employees.

From FY 2021, the promotion of health and productivity management has been set forth in the Nippon Soda Group’s CSR Activity Policy, as a management resource that increases corporate competitiveness and brings about the capacity for sustainable growth. We will continue to support the health maintenance of employees, which is essential to the safety of manufacturing sites and stable operations, through constant monitoring. We will also work to improve the rate of employees undergoing complete physical examinations, follow-up on those undergoing periodic medical examinations with a target of a 5% annual improvement, conduct stress checks and follow ups, and provide mental and physical health education.

- Health & Productivity Management Organization Recognition Program Certification System https://www.meti.go.jp/english/press/2024/0311_002.html

About Health and Productivity Management

Nisso Group Health and Productivity Management Promotion Declaration

The Group considers people to be the most important corporate resource for enhancing corporate competitiveness and achieving sustainable growth.

It is fundamentally important to maintain health, both physically and mentally, to create a workplace where individual employees can work willingly and actively. In this context, we implement and promote health and productivity management as an important issue in business management.

To maintain and promote the good health of employees and their families, the Company, the Nisso Health Insurance Association, labor unions, and the employees’ association will make concerted efforts to take various proactive measures.

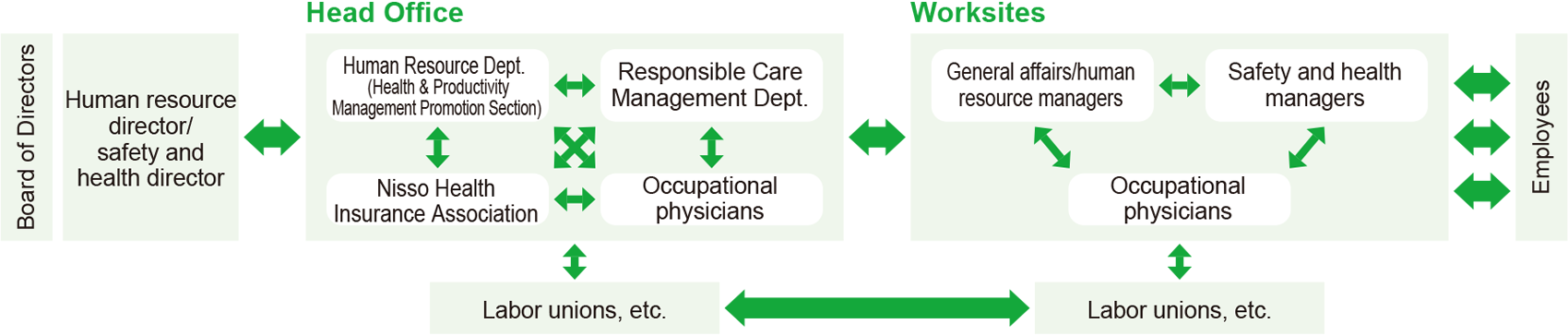

In order to actualize our Health and Productivity Management Promotion Declaration, under the supervision of the human resource director and safety and health director, we will promote cooperation between the Head Office and each worksite, and implement various measures. In FY 2023, we set up the Health and Productivity Management Promotion Section within the Human Resources Department as a dedicated supervisory organization. The section is responsible for companywide health and productivity management initiatives and for reinforcing collaboration between business sites.

To date, we have sought to prevent lifestyle-related diseases through the promotion of complete physical examinations, specific examinations, and specific health guidance. We have also worked to educate employees on the importance of influenza vaccinations and provide them with opportunities to receive them. More recently, we have offered employees education and guidance on ways to further enhance measures to prevent lifestyle-related diseases, and are carrying out more than the legally required number of health examination initiatives. For example, we are working to secure opportunities for employees to undergo health examinations, and ensuring thorough supervision of overtime work to ensure a proper work-life balance and maintain employees’ health.

Message from the President

Since our establishment in 1920, we have continued to use chemistry to provide new value to society, continuing our business activities so that we can contribute to the development of society. To ensure business continuity and development, to date we have considered our employees’ health mainly through occupational safety and health measures.

Meanwhile, there is currently growing concern that declining birthrates and aging populations, soaring social security costs, and other issues will have a major impact on social systems. Therefore, in addition to occupational safety and health, more than ever before corporations are being called upon to maintain and promote their employees’ health.

Moreover, maintaining and improving health is incredibly important to enhancing the quality of life for our employees. Healthy employees can also boost motivation and bring energy to their respective organizations, and in turn lead to improved company achievements. As such, health is vitally important to the Company.

And so, to enhance our corporate value over the medium to long term by maintaining and improving our employees’ health, on top of our existing initiatives, we will proactively drive health and productivity management through efforts to prevent absenteeism and presenteeism, and the implementation of measures that can improve job satisfaction and fulfillment.

Eiji Aga

Representative Director, President

Nippon Soda Co., Ltd.

Mental Health Care

Our mental healthcare program consists of ❶ self-care, ❷ care by administrators in the workplace, ❸ care by occupational healthcare staff and other specialists at each workplace, and ❹ care by external parties.

A stress check is conducted once a year to support ❶ self-care by employees and, ❸ care by occupational healthcare staff and other specialists at each workplace. To improve ❷ care by administrators in the workplace, lectures on mental health given by external specialists are organized.

Consultations with qualified mental health specialists by phone or face-to-face are also available as part of efforts to provide ❹ care by external parties. In addition, lectures on mental health are provided by an external organization to help employees manage their own mental health.

Education and Lectures on Occupational Safety

Heatstroke prevention education

(Takaoka Plant, May 31, 2023)

Experiential education relating to the odor of phosgene gas

(Takaoka Plant, June 13, 2023)

Traffic lecture

(Nihongi Plant, September 26, 2023)

Health lecture

(Nihongi Plant, October 5, 2023)

Mental health supervisor education

(Takaoka Plant, December 4 and 11, 2023)

Harassment seminar

(Chiba Plant, January 22, 2024)

General lifesaving class

(Chiba Plant, February 15 and 16, 2024)

Health lecture

(Nihongi Plant, February 28, 2024)

Health lecture

(Mizushima Plant, March 27, 2024)

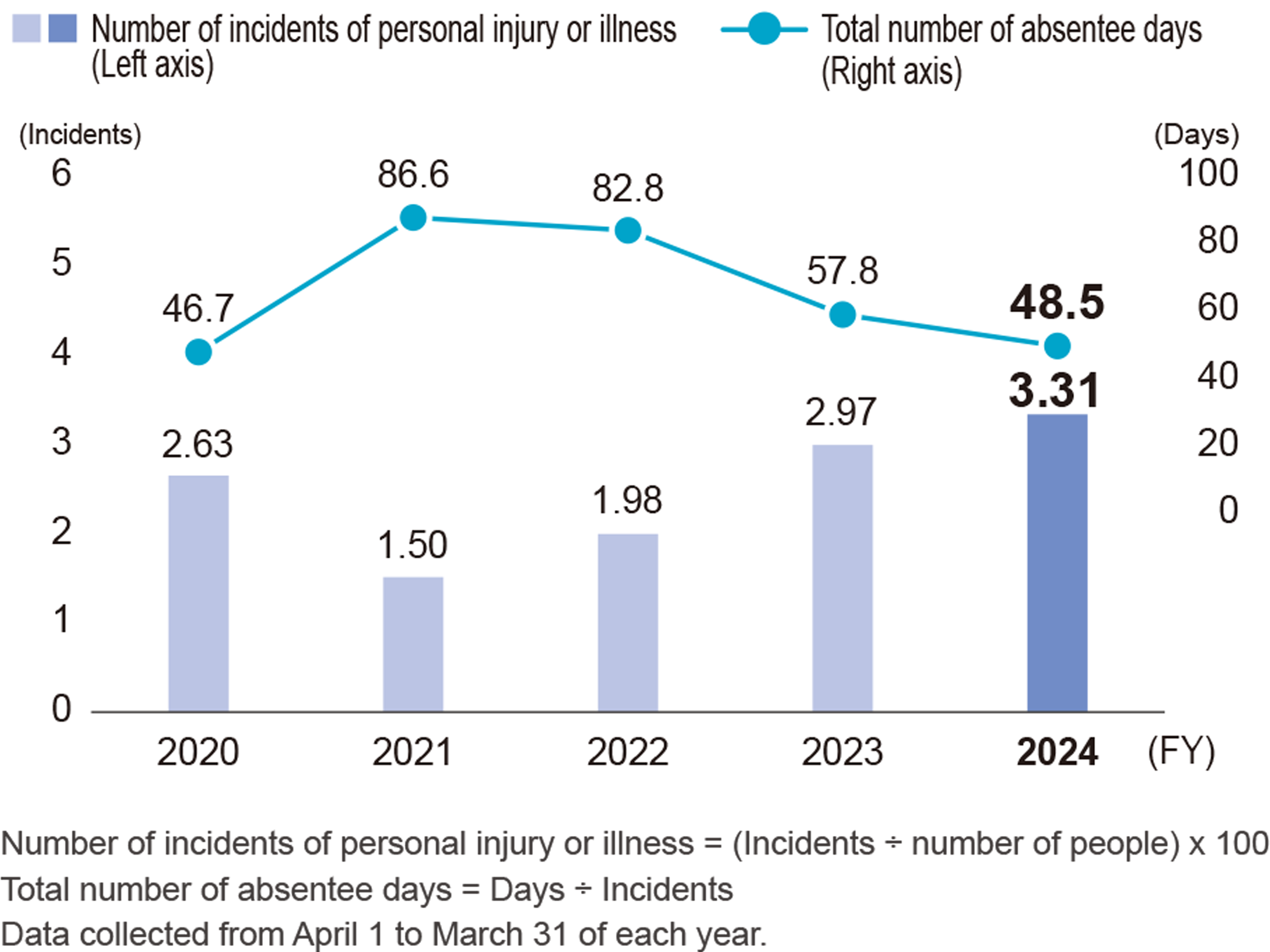

Number of incidents of personal injury or illness (per 100 persons) and total number of absentee days (per incident)

With the aim of achieving the goal of zero occupational accidents, we will continue our efforts to reduce risks through continuous risk assessment, strengthen measures to prevent human error, and enhance safety activities. To help employees maintain and improve their health, we continue to implement good health maintenance activities.

- 1.Occupational accidents resulting in an absence from work or no absence

- No accidents

- Initiatives to ensure no accidents

- 1)Conduct risk assessments to reduce risk

- 2)Strengthen measures to prevent human error

- 3)Implement activities to ensure safety

- 4)Implement disaster prevention activities for young employees and less-experienced employees

Strengthen hands-on training facilities and training system

- 2.Promotion of health and productivity management: Improvement of health literacy

- Gauge current level of health literacy

- Follow-up of those undergoing periodic medical examinations

- Mental health checkups and follow-ups

- Formulate and implement various health measures and educational programs