Environmental Protection

As work to tackle global issues such as global warming and resource depletion advances, shifts in the structure of industry are becoming more apparent. At the Nippon Soda Group, in addition to engaging in environmental protection activities to minimize the negative impact of our own business, by creating new value through the power of chemistry and ensuring the continuous development of our business, we are aiming to achieve a sustainable society and improve our corporate value.

- Continuing efforts to prevent environmental pollution, complying with laws and regulations, and promoting other environmental activities.

- Reduction of environmental burden associated with business operations (prevention of global warming, and reduction in the amount of waste generated and amount of final disposal at landfill).

- Development of products and processes with less environmental burden.

- Implementation of an environmental management system.

Reduction in energy consumption while maintaining productivity. - Water resources conservation.

- Reduction of impact on biodiversity and ecosystems.

FY 2024 targets and achievement levels (KPIs)

(Achievement levels ◎:≥ 90% ○:80-90% △:60-80% ×: ≤ 60%) Red text: KPIs

Environmental Protection

Responses to Climate Change Issues

Efforts to prevent global warming are critical. Nippon Soda participates in the Keidanren Carbon Neutrality Action Plan, a voluntary action plan promoted by Keidanren (Japan Business Federation). Under the action plan, we are promoting energy saving to achieve the greenhouse gas (GHG) emissions reduction targets.

We have also set medium- to long-term reduction targets, aiming to reduce the Group’s GHG emissions by more than 20% by FY 2026 (compared with FY 2014) and more than 30% by FY 2031 (compared with FY 2014).

Reduction of energy consumption and greenhouse gas emissions

We are engaged in a wide range of measures to reduce our energy intensity. These efforts include replacing our aging equipment with high-efficiency equipment, streamlining and increasing labor efficiency in our production process, and implementing energy-saving measures. Furthermore, we use the Ministry of the Environment’s Basic Guidelines on Accounting for Greenhouse Gas (GHG) Emissions Throughout the Supply Chain when calculating GHG emissions from our business activities (Scope 1, Scope 2) as well as indirect emissions from outside our business activities (Scope 3). In this way, we work to reduce emissions throughout the supply chain.

Greenhouse Gas Emissions throughout the Supply Chain

Scope 1 emissions 46,462t-CO2

Scope 2 emissions 83,318t-CO2

Scope 3 emissions 158,477t-CO2

| Categories of Scope 3 | Emissions by category |

|---|---|

| Purchased raw materials / services | 137,886t-CO2 |

| Capital goods | 15,878t-CO2 |

| Fuel, etc., not included in Scope 1 or 2 | Not calculated |

| Transport, delivery (upstream) | 2,951t-CO2 |

| Waste generated from business | Not calculated |

| Business trips | 1,487t-CO2 |

| Employee commuting | 275t-CO2 |

| Leased assets (upstream) | None |

| Transport and delivery (downstream) | Not calculated |

| Processing of sold products | Not calculated |

| Use of sold products | Not calculated |

| Disposal of sold products | Not calculated |

| Leased assets (downstream) | None |

| Franchise | None |

| Investment | Not calculated |

- Note: All figures required for calculations, such as emissions intensity, are taken from the Ministry of the Environment’s “Emission Factor Database for calculating greenhouse gas emissions, etc., by organizations throughout the supply chain (ver. 3.0).”

Forestry activities and CO2 absorption

Forests play key roles as carbon sinks in the prevention of climate change. Nisso Shoji Co., Ltd. owns approximately 56 hectares of land near the headwaters of the Keta River, a tributary of the Tenryu River. Here, based on afforestation and superficies rights agreements, Shizuoka Prefecture is engaged in the creation and management of a manmade Japanese cedar and cypress forest. In addition to being designated a headwater conservation forest, the forest has also acquired FSC* certification in recognition of sustainable forest management. In this way, the Group is contributing to healthy forest development.

- * The Forest Stewardship Council® is an international non-profit organization that aims to promote responsible management of forests worldwide.

FSC certification shows that an independent third-party organization has recognized that appropriate management systems are in place to ensure forest conservation.

Use of renewable energy

At the Nihongi Plant, we draw industrial water from a nearby river and use the difference in elevation when returning it to the river for small-scale hydroelectric power generation. Since its construction in 1940, the plant has been effectively using this energy in its production activities. Moving forward, we will carefully maintain the power generation facilities at the plant as a stable source of renewable energy.

At the Takaoka Plant, we began purchasing renewable electricity to help reduce our GHG emissions. In FY 2024, we replaced the equivalent of 10% of electricity used in the plant with renewable electricity, and we plan to increase this ratio further from FY 2025 onwards.

At the Chiba Plant, we are moving forward with capital investment plans to install solar panels within the plant grounds, aiming for completion in the second half of FY 2025. The installation of solar power generation systems will enable an annual reduction in CO2 emissions of 1,140 t.

In January 2024, the JP Tower, where our head office is located, introduced the Green Basic Plan* offered by TEPCO Energy Partner, Inc. This will ensure net-zero CO2 emissions from electricity used at the building.

Moving forward, we will accelerate our efforts for decarbonization through further examinations of the introduction of renewable energy at other worksites.

- * Green Basic Plan: An electricity plan from TEPCO Energy Partner, Inc. that supplies electricity derived from renewable energy sources such as solar, wind, and hydro power, to ensure net-zero CO2 emissions.

Small hydropower facilities of the Nihongi Plant

Solar panels at the Chiba Plant

Promotion of energy saving by the Logistics Department

At Nippon Soda, we are working to reduce the energy intensity in our Logistics Department. As a specified consignor under the Act on the Rational Use of Energy, every year we submitted a periodic report and a medium- to long-term plan to the Ministry of Economy, Trade and Industry. However, as we no longer manufacture and sell potassium products in line with structural reforms at the Nihongi Plant, our annual volume of transported products has significantly fallen below the 30 million ton-kilometer standard for specified consignors. As a result, our designation as a specified consignor was withdrawn, and we are no longer required to submit periodic reports to the Ministry of Economy, Trade and Industry. Despite this change in circumstances, we will continue working to improve logistics efficiency and reduce environmental burden through measures such as modal shifts in transportation, reducing the frequency of trips by using larger transport containers, and adjusting distribution routes. In 2013, our modal shift initiatives were highly acclaimed, and we were certified with the Eco Rail Mark from the Ministry of Land, Infrastructure, Transport and Tourism.

Effective Use of Resources and Reduction of Industrial Waste

We participate in the Voluntary Action Plan for Establishing a Sound Material-Cycle Society promoted by Keidanren (Japan Business Federation). Under the action plan, we promote industrial waste reduction to achieve the target amount of reduction in the final disposal of industrial waste at landfill.

Proper management of industrial waste and reduction of the final disposal of industrial waste at landfill

As one of its efforts to help build a sound material-cycle society, Nippon Soda reduces the amount of industrial waste emissions from a long-term perspective and, at the same time, promotes the recycling of industrial waste items and implements other measures to reduce the final disposal amount of industrial waste at landfill.

Zero emissions

In FY 2024, Nippon Soda achieved zero emissions.* We will promote the further reduction of industrial waste to continue achieving zero emissions.

- * When the ratio of the amount of final disposal of industrial waste at landfill compared with the amount transported to the industrial waste disposal facility is small. We define to be “Zero emissions” as when the ratio of landfill waste is 2% or less.

PCB (polychlorinated biphenyl) waste

Each Nippon Soda site properly stores and manages condensers, transformers, mercury lamp ballasts, and other items which contain PCBs and disposes of them appropriately and systematically in accordance with the Act on Special Measures concerning Promotion of Proper Treatment of PCB Wastes, which was revised in 2016.

Atmosphere and Water Quality Conservation

Nippon Soda implements various measures to protect the atmosphere and water quality, such as reducing emissions of chemical substances subject to the PRTR system and reducing emissions of harmful substances into rivers and other bodies of water, in accordance with the Air Pollution Control Act, the Water Pollution Prevention Act, and the latest regulatory trends.

Reduction of chemical substances specified by the PRTR System

We are making efforts to reduce emissions of Class I Designated Chemical Substances specified by the PRTR System, one of two sections contained in the Act on Confirmation, etc. of Release Amounts of Specific Chemical Substances in the Environment and Promotion of Improvements to the Management Thereof.

Reduction of emissions of harmful substances into the atmosphere

Twelve chemicals among those categorized as priority substances under the Air Pollution Control Act are designated as voluntarily controlled chemical substances by the Japan Chemical Industry Association (JCIA). Of the twelve chemicals, the Company currently handles the following six substances: chloroform, dichloromethane, 1,2-dichloroethane, ethylene oxide, 1,3-butadiene and benzene. We are implementing measures to reduce the emissions of these six substances.

Reduction of air pollutant emissions

Nippon Soda promotes the reduction of emissions of sulfur oxide (SOx), nitrogen oxide (NOx), and soot and dust. Emissions of these substances from stationary sources are controlled under the Air Pollution Control Act.

Actions to conform to the Fluorocarbons Emission Control Act

To comply with the Fluorocarbons Emission Control Act, we implement periodic inspections by those with expertise, simplified inspections by the Inspection Manager, measures to prevent fluorocarbon emissions, and other required activities at one worksite at a time.

Reduction of harmful substance emissions into rivers and other bodies of water

Nippon Soda has made its voluntary standards stricter than the national regulatory values and the standard values agreed with local municipalities. Based on these strict values, we manage water quality through the monitoring of pollutants and purification at wastewater treatment plants.

Preservation of Biodiversity

Nippon Soda has been taking measures to reduce its environmental burden, use water resources effectively, and prevent pollution of air, water, and soil, mainly in areas where its production sites are located. In recent years, we have added conservation of biodiversity as a priority issue and have been carrying out viable activities that can be implemented at each of our worksites.

Breeding of killifish originating from the Sakawa River system

(Research & Innovation Center [Odawara])

Odawara City, Kanagawa Prefecture, has been promoting protection activities for killifish, which are listed as an Endangered Species Category II by the Ministry of the Environment. In 1999, we conducted the Medaka-no Otosan Okasan Sato-oya Seido (“Killifish Fosterparent Program”), which involves working to protect their habitat and helping to pass their genes down to the next generation.

Breeding of killifish originating from the Sakawa River system

Supporting the protection of himekomatsu (Japanese white pine), a critically endangered species (Chiba Plant)

The Chiba Plant has continued with the Himekomatsu Supporter project which started in 2016 to protect himekomatsu, an endangered tree species in Chiba Prefecture.

Participation in the CropLife JAPAN (CL Japan) Honeybee Friendship Plan

As one activity aimed at achieving its vision, since FY 2021 CL Japan* has operated the Honeybee Friendship Plan, through which it uses any available space at its member companies’ offices and land to grow plants for pollinating insects.

At Nippon Soda we fully support the Honeybee Friendship Plan and various efforts are underway at each of our worksites.

- * Name changed from Japan Crop Protection Association to CropLife JAPAN in May 2024

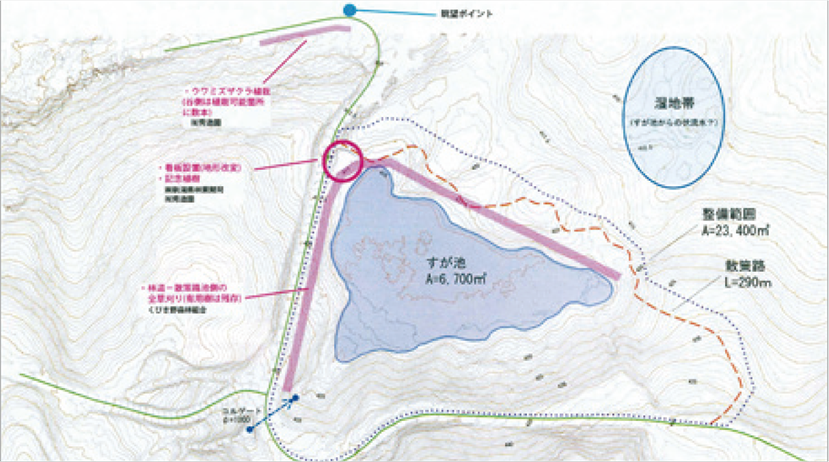

Environmental protection activities through the Nippon Soda Group Forest

On the occasion of the 100th anniversary of our establishment, we began initiatives to protect greenery and water sources as a contribution to the achievement of the SDGs. Nippon Soda established the Nippon Soda Group Forest within the Joetsu KUWADORI Community Forest in Joetsu City, Niigata Prefecture, the location of the Company’s origin, and continues to make donations to the National Land Afforestation Promotion Organization in order to contribute to the creation of a forest of biodiversity and environmental protection.

Nippon Soda Group Forest blueprint

Water level at the Suga Lake (July 18, 2023)

We will make continuous efforts to minimize the impact of our business activities on the environment. Our efforts to protect the environment will include energy saving, resource saving, reduction of greenhouse gas emissions, conservation of water resources, preservation of biodiversity, and reduction of the impact on ecosystems.

- 1.Environmental issues: Zero events

- 2.Energy

- 2-1.Energy intensity (excluding logistics): Annual improvement of 1% (based on production volume)

- 2-2.Energy intensity in logistics: Annual improvement of 1% (based on sales)

- 3.Reduction in greenhouse gas emissions

- Nippon Soda Group CO2 (GHG) emissions:

More than 20% reduction by FY 2026

More than 30% reduction by FY 2031 (compared with FY 2014)

- 4.Water resources conservation

- Monitor water resources and promote efficient water use

- 5.Waste

- 5-1.Amount of final disposal at landfill: Annual reduction of 3%

- 5-2.Continuation of zero emissions: 2% or less

- 5-3.Reduction of waste plastic, etc.

- 6.Emissions of harmful substances into the atmosphere: Annual reduction of 1%

- 7.Reduction of impact on biodiversity and ecosystems