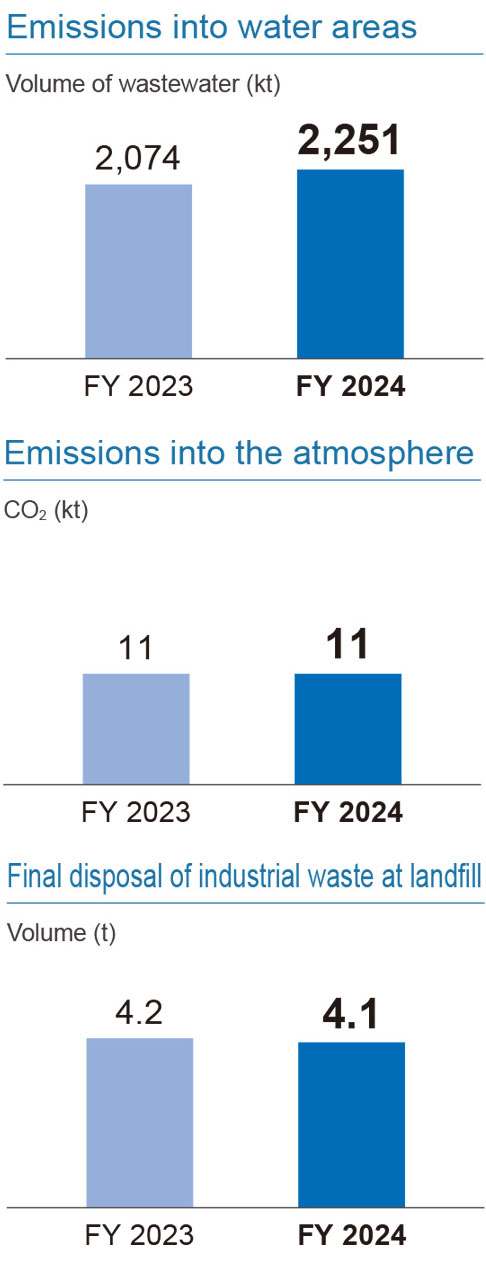

CSR Activities at Plants

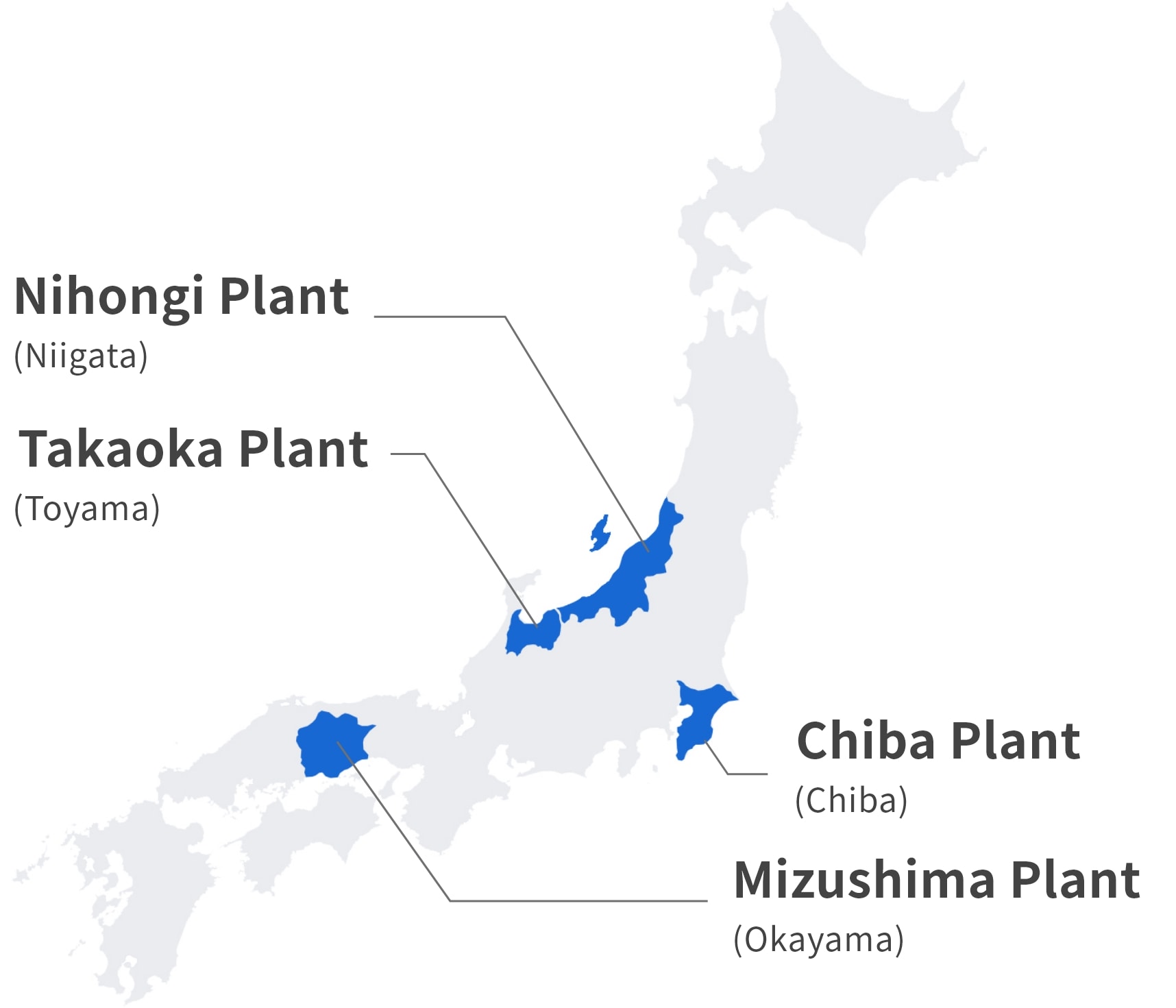

Nihongi Plant

- Address / Contact

-

950 Fujisawa, Nakago-ku, Joetsu, Niigata 949-2392

TEL: +81-255-81-2300 FAX: +81-255-81-2341 - Major products manufactured

- Alcoholate, NISSO HPC, faropenem sodium, MOSPILAN, NISSORUN, NISSO HI-CHLON, HIDION, DANYOTE, KINOPROL (MIGIWA), etc.

- Number of employees

- 286 (As of the end of March 2024)

- Partner companies

-

198 employees (As of the end of March 2024)

ISO 14001: Certified in March 2000

ISO 9001: Certified in August 1995

ISO 45001: Transitioned in September 2020

(Certified in April 2009 with OHSAS 18001)

Executive Officer, Nihongi Plant Manager

The Nihongi Plant is located at the foot of the nature-rich Mt. Myoko—one of the 100 Famous Japanese

Mountains—and began operations in February 1920 as the very origins of the Nippon Soda Group, celebrating its 100th anniversary on February 1, 2020. We have continued our operations while giving full consideration to the natural environment and gained the understanding and support of local communities and stakeholders through various exchange programs.

We conduct CSR activities involving all employees, and contribute to realizing a vibrant society through business activities that consider not only process safety and disaster prevention, but also safety and health, environmental conservation, and quality assurance. Our efforts are also focused on being a plant that is trusted by local residents, as well as everyone working at the plant. In recent years, we have participated in a project to create a new type of community together with the Nakago-ku General Office, the community development association, elementary and junior high schools, and other local residents.

To work together to achieve further growth at the Nihongi Plant, we have defined our plant policy for 2024 as “steady execution of various measures.” To set out on a new path for the next 100 years, we will evolve our business structure from one centered on predominantly inorganic industrial chemicals to one driven by new products with high added-value, such as agrochemicals, pharmaceuticals, pharmaceutical additives, and functional chemicals. Moreover, to achieve our key plant goals—zero accidents, zero disasters, and safe, stable, and anshin* operations—we will continue to engage in activities for environmental protection, process safety and disaster prevention, and safety and health.

- * Anshin has three meanings: psychological peace of mind, physical peace of mind, and peace of mind for families.

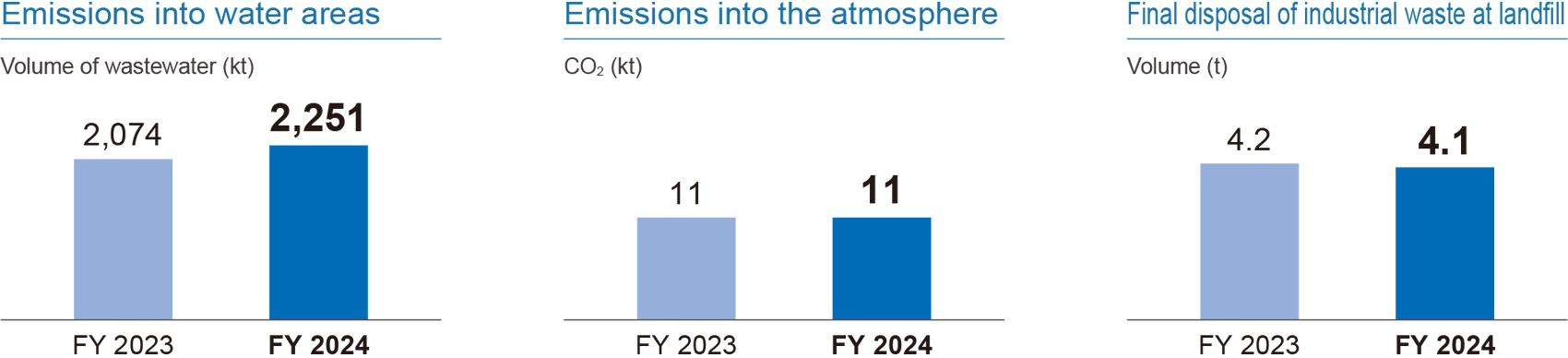

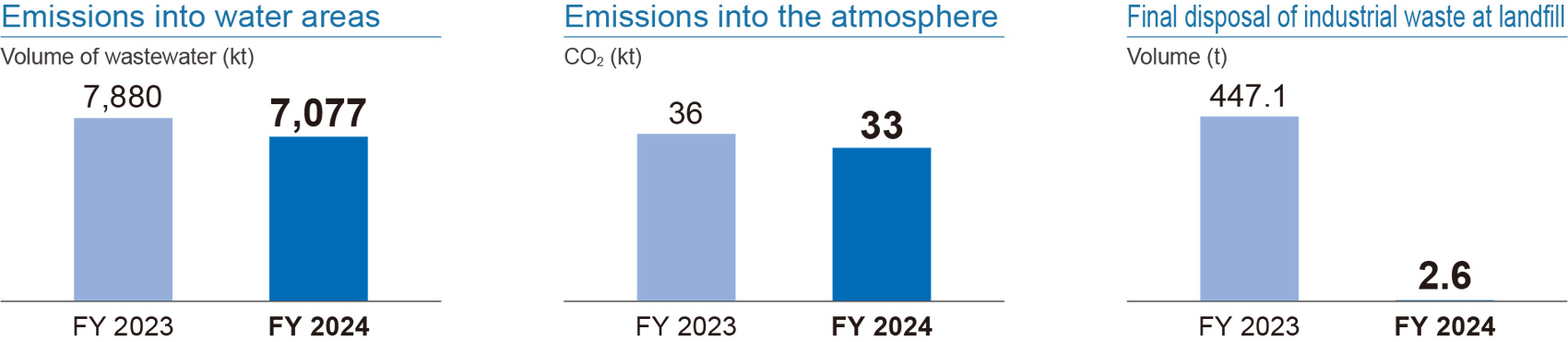

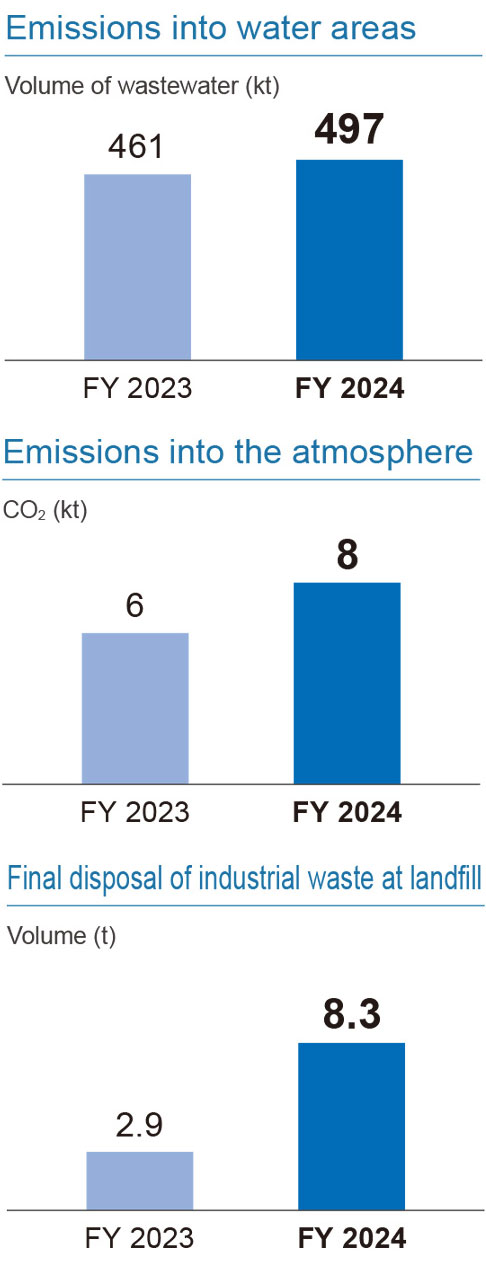

Environmental Data for FY 2024

Unit: t/year (volume of wastewater: kt/year, CO2: kt/year)

Note: The figures in parentheses represent the difference from results in the previous fiscal year. “+” denotes an increase, while “-” denotes a decrease.

| Emissions into water areas | Emissions into the atmosphere | Final disposal of industrial waste at landfill |

|||||

|---|---|---|---|---|---|---|---|

| Volume of wastewater | BOD | COD | CO2 | NOx | SOx | Soot and dust | ー |

|

7,077 (-803) |

9.0 (-5.5) |

― |

33 (-3) |

15.7 (-1.6) |

1.4 (-0.2) |

10.6 (+0.1) |

2.6 (-444.5) |

FY 2024 Amount of PRTR System Substance Emissions

Note: The figures in parentheses represent the difference from results in the previous fiscal year. “+” denotes an increase, while “-” denotes a decrease.

| Toluene | Fluorine | Chloroform | ||||||

|---|---|---|---|---|---|---|---|---|

| Emission amount | Transported amount |

Emission amount | Transported amount |

Emission amount | Transported amount |

|||

| Air | Water | Air | Water | Air | Water | |||

|

31.29 (-0.68) |

0.00 (0.00) |

45.57 (+25.57) |

0.00 (0.00) |

0.00 (0.00) |

2.19 (+0.93) |

2.45 (-0.58) |

0.00 (0.00) |

0.00 (0.00) |

PRTR substances: 17 substances Total emission amount: 35.28 t Total amount transported: 47.76 t

External Communication

| No. of environmental monitors | No. of times information was provided (of which was related to environmental monitoring) |

|---|---|

| 5 | 1(0) |

Takaoka Plant

- Address / Contact

-

300 Mukaino-honmachi, Takaoka, Toyama 933-8507

TEL: +81-766-26-0206 FAX: +81-766-26-0300 - Major products manufactured

- Caustic soda, hydrochloric acid, TODI, phosphorous chloride, organotitanium, secondary battery materials, TOPSIN-M, TRIFMINE, PYTHILOCK, pesticide formulation products, etc.

- Number of employees

- 352 (As of the end of March 2024)

- Partner companies

-

141 employees (As of the end of March 2024)

ISO 14001: Certified in November 2000

ISO 9001: Certified in June 1995

ISO 45001: Transitioned in November 2020

(Certified in November 2005 with OHSAS 18001)

Executive Officer, Takaoka Plant Manager

Takaoka Plant started operation in 1934 by the Oyabe River in Takaoka City, Toyama Prefecture. The area sits amid the Tateyama mountain range, the Hida mountains and the Hakusan mountain range, which provide abundant water, and by Toyama Bay, which is rich in natural resources. Supported by abundant water and electricity, we manufacture basic chemical products through the electrolysis of sodium chloride (salt), which is the basis of the chemical industry. Using these chemical products as ingredients, we also manufacture functional chemicals and agrochemicals, essential items in modern society.

There are many issues associated with the process of manufacturing these products, including large amounts of electricity consumption and the generation of waste. Taking these issues seriously, we have been engaged in various efforts for conserving the environment, such as energy reduction and waste recycling. Since Takaoka Plant is a chemical plant, all employees working here handle hazardous substances professionally and safely. We also place strong emphasis on ensuring safety and disaster prevention so that even if an accident does occur we can minimize damage and prevent any impact on the environment or on residents in nearby communities.

We recognize that it is the responsibility of our plant and our company to ensure the safety and security of the environment of Toyama Bay, one of the most beautiful bays in the world, as well as the local communities.

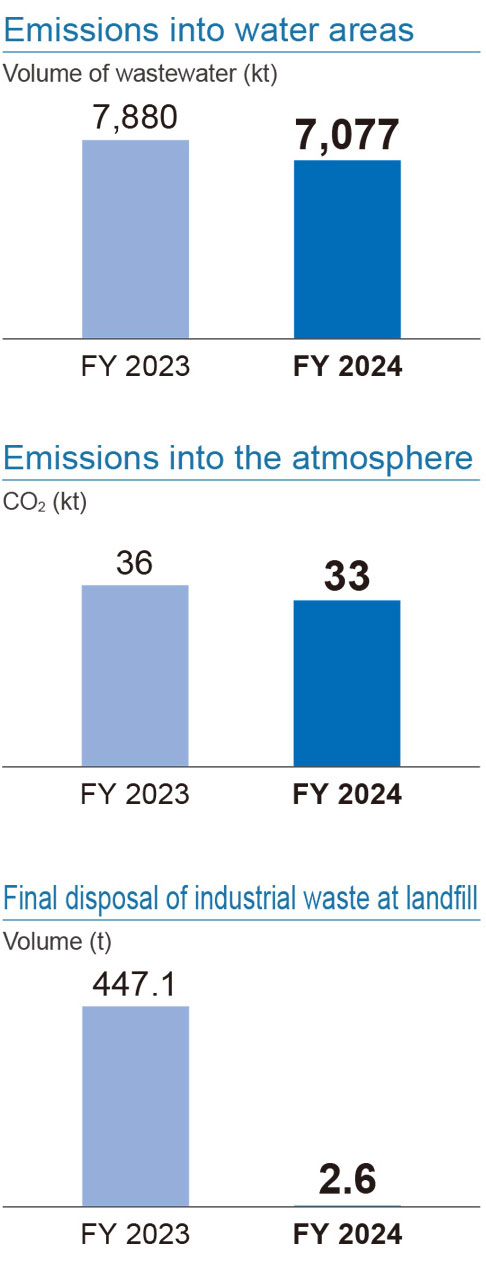

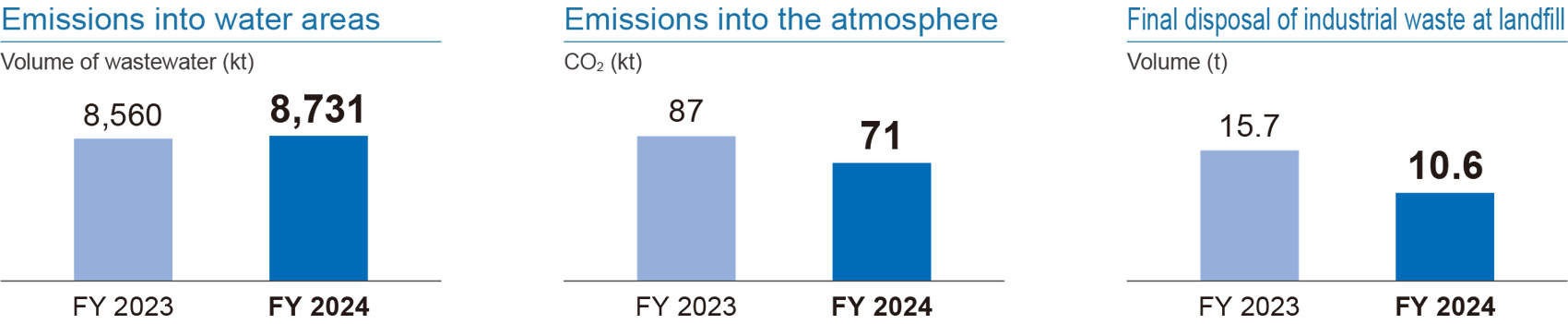

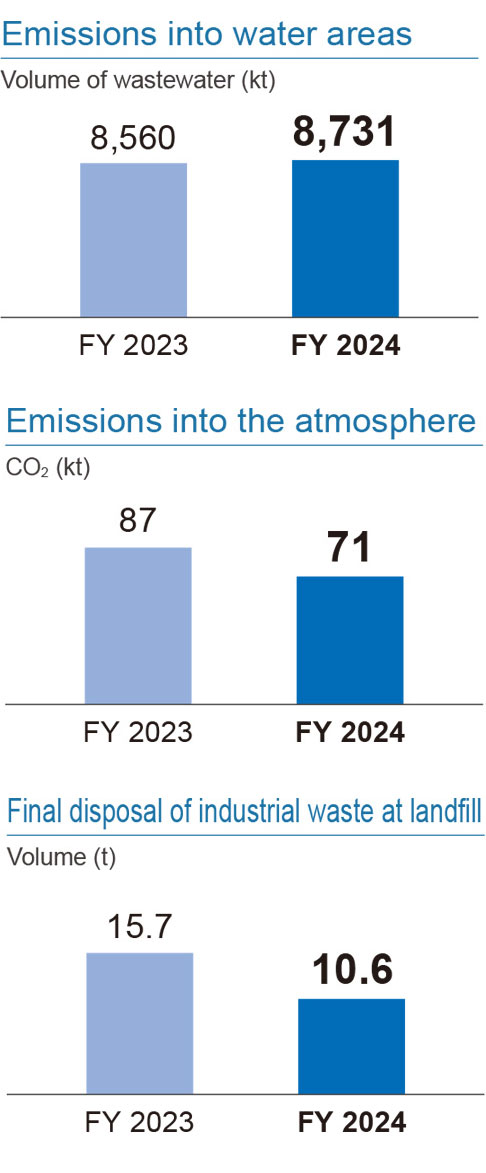

Environmental Data for FY 2024

Unit: t/year (volume of wastewater: kt/year, CO2: kt/year)

Note: The figures in parentheses represent the difference from results in the previous fiscal year. “+” denotes an increase, while “-” denotes a decrease.

| Emissions into water areas | Emissions into the atmosphere | Final disposal of industrial waste at landfill |

|||||

|---|---|---|---|---|---|---|---|

| Volume of wastewater | BOD | COD | CO2 | NOx | SOx | Soot and dust | ー |

|

8,731 (+171) |

65.7 (-19.2) |

92.5 (-11.3) |

71 (-16) |

28.0 (-1.9) |

83.7 (-27.3) |

0.9 (-1.2) |

10.6 (-5.1) |

FY 2024 Amount of PRTR System Substance Emissions

Note: The figures in parentheses represent the difference from results in the previous fiscal year. “+” denotes an increase, while “-” denotes a decrease.

| Toluene | Chlorobenzene | Chloroform | ||||||

|---|---|---|---|---|---|---|---|---|

| Emission amount | Transported amount |

Emission amount | Transported amount |

Emission amount | Transported amount |

|||

| Air | Water | Air | Water | Air | Water | |||

|

0.13 (-0.05) |

0.00 (0.00) |

3.06 (-6.96) |

8.83 (-2.86) |

1.16 (-0.40) |

251.47 (-90.57) |

0.06 (-0.04) |

0.00 (-0.01) |

33.56 (-24.18) |

PRTR substances: 22 substances Total emission amount: 11.00 t Total amount transported: 321.50 t

- * In FY 2024, CO2 emissions have been calculated assuming that 10% of the purchased electricity is derived from renewable energy sources (pre-correction: 76,000 t / year; post-correction: 71,000 t / year).

External Communication

| No. of environmental monitors | No. of times information was provided (of which was related to environmental monitoring) |

|---|---|

| 12 | 5(4) |

Mizushima Plant

- Address / Contact

-

2767-12 Kojima-shionasu, Kurashiki, Okayama 711-0934

TEL: +81-86-475-0036 FAX: +81-86-475-0039 - Major products manufactured

-

Sodium cyanide, potassium cyanide, NISSO DAMN

(diaminomaleonitrile) - Number of employees

- 49 (As of the end of March 2024)

- Partner companies

-

22 employees (As of the end of March 2024)

ISO 14001: Certified in October 2001

ISO 9001: Certified in January 1999

ISO 45001: Transitioned in January 2021

(Certified in January 2009 with OHSAS 18001)

Mizushima Plant Manager

Mizushima Plant started operations in 1969 in the Mizushima Industrial Area, which extends from the mouth of the Takahashi River in Okayama Prefecture and has access to abundant supplies of industrial water, oil, and electricity, while being conveniently located for land and sea transportation. In its early days, the plant was supplied with raw materials from neighboring companies. Keenly aware of the highly toxic cyanide that the plant uses during production, all employees working at the plant, including those of partner companies, work with the necessary awareness required for the safe handling of hazardous materials. Furthermore, we also engage in CSR activities in compliance with requirements, including handling ingredients and products, correctly wearing protective clothing, and working safely.

As announced on our website in March 2024, the decision has been made to close the Mizushima Plant during FY 2026. However, even as we bring production to a close, we will continue working toward the key goal in our plant’s policy to achieve zero accidents and disasters. We will therefore continue with inspection patrols, emergency drills, education, and other activities to ensure occupational safety and health.

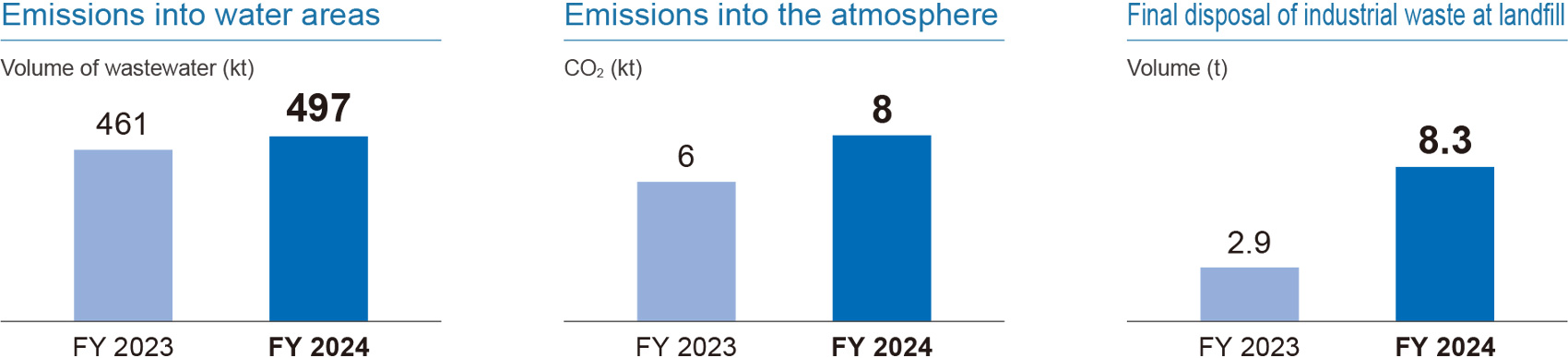

Environmental Data for FY 2024

Unit: t/year (volume of wastewater: kt/year, CO2: kt/year)

Note: The figures in parentheses represent the difference from results in the previous fiscal year. “+” denotes an increase, while “-” denotes a decrease.

| Emissions into water areas | Emissions into the atmosphere | Final disposal of industrial waste at landfill |

|||||

|---|---|---|---|---|---|---|---|

| Volume of wastewater | BOD | COD | CO2 | NOx | SOx | Soot and dust | ー |

|

497 (+36) |

― |

2.0 (+0.2) |

8 (+2) |

4.6 (-1.0) |

0.0 (0.0) |

0.0 (0.0) |

8.3 (+5.4) |

FY 2024 Amount of PRTR System Substance Emissions

Note: The figures in parentheses represent the difference from results in the previous fiscal year. “+” denotes an increase, while “-” denotes a decrease.

| Xylene | Inorganic cyanides | Acetonitrile | ||||||

|---|---|---|---|---|---|---|---|---|

| Emission amount | Transported amount |

Emission amount | Transported amount |

Emission amount | Transported amount |

|||

| Air | Water | Air | Water | Air | Water | |||

|

0.00 (0.00) |

0.00 (0.00) |

0.03 (+0.02) |

0.19 (+0.08) |

0.002 (+0.001) |

0.01 (-0.01) |

0.00 (0.00) |

0.00 (0.00) |

0.34 (+0.09) |

PRTR substances: 4 substances Total emission amount: 0.192 t Total amount transported: 0.38 t

Chiba Plant

- Address / Contact

-

12-8 Goiminami-kaigan, Ichihara, Chiba 290-8530

TEL: +81-436-23-2007 FAX: +81-436-22-6588 - Major products manufactured

- NISSO-PB, VP-POLYMER, TITA BOND, TAKE-ONE

- Number of employees

- 136 (As of the end of March 2024)

- Partner companies

-

64 employees (As of the end of March 2024)

ISO 14001: Certified in July 2000

ISO 9001: Certified in August 1997

ISO 45001: Transitioned in February 2021

(Certified in February 2008 with OHSAS 18001)

Chiba Plant Manager

The plant started operations in 1969 as Nissou Kasei Co., Ltd., in a section of the Keiyo Industrial Zone, which faces the east side of Tokyo Bay. In 1999, it became the Nippon Soda Chiba Plant, which it has remained to the present. Rather than large-scale generic petrochemical products for general use, the Chiba Plant produces chemicals with a focus on specialty chemicals at mid-sized plants. Common applications for our products include liquid polybutadiene as a raw material in acrylic paints used in smartphones and for printing plates, VP-POLYMER as a widely used, key material for photoresists, which are essential for the manufacture of semiconductors.

As a chemical plant located in the greater Tokyo region, a great deal is required of us. Our foremost priority is to ensure zero accidents and zero disasters, and with safety and reliability as our watchwords, all who work at the plant engage in activities for environmental protection, process safety and disaster prevention, and safety and health. By providing a stable supply of various products that support people’s lives, our aim is to become a plant that is valued by all.

Environmental Data for FY 2024

Unit: t/year (volume of wastewater: kt/year, CO2: kt/year)

Note: The figures in parentheses represent the difference from results in the previous fiscal year. “+” denotes an increase, while “-” denotes a decrease.

| Emissions into water areas | Emissions into the atmosphere | Final disposal of industrial waste at landfill |

|||||

|---|---|---|---|---|---|---|---|

| Volume of wastewater | BOD | COD | CO2 | NOx | SOx | Soot and dust | ー |

|

2,251 (+177) |

― |

29.5 (+12.6) |

11 (―) |

― | ― | ― |

4.1 (-1.0) |

FY 2024 Amount of PRTR System Substance Emissions

Note: The figures in parentheses represent the difference from results in the previous fiscal year.

“+” denotes an increase, while “-” denotes a decrease.

| Toluene | Tetrahydrofuran | 1,3-butadiene | ||||||

|---|---|---|---|---|---|---|---|---|

| Emission amount | Transported amount |

Emission amount | Transported amount |

Emission amount | Transported amount |

|||

| Air | Water | Air | Water | Air | Water | |||

|

14.41 (+7.12) |

0.00 (0.00) |

0.15 (0.00) |

3.39 (―) |

0.00 (0.00) |

3.58 (―) |

2.28 (-0.32) |

0.00 (0.00) |

0.00 (0.00) |

PRTR substances: 12 substances Total emission amount: 22.23 t Total amount transported: 3.73 t

* Tetrahydrofuran was added in FY 2024