Nutraceuticals and Food

General Information

CELNY

Hydroxypropyl Cellulose (HPC) is a water soluble, non-ionic derivative of cellulose, an abundant and natural polysaccharide found in all plants. CELNY™ brand is a high quality grade of HPC for food and nutraceutical use. CELNY is available in a wide range of viscosities and particle sizes to suit your application needs. It is food use approved globally, non-GMO, non-dairy, gluten and common allergen free. CELNY HPC applications include tablet binder, film forming agent, and stabilizer.

Our special low viscosity grades offer unique advantages for tablet formulations:

Excellent tablet hardness/friability with fast disintegration and active release times

Ease of use in wet granulation and coating applications

Highest compressibility at low usage level in dry binding applications

Features of CELNY

- Highest efficiency tablet binder

- Soluble in water and polar organic solvents

- Nonionic, nonreactive, nontoxic

- Eight different molecular weight grades produced designed for immediate or sustained release

- Three different particle size grades tailored to wet or dry application

- Minimal lot-to-lot variability enabling Quality By Design

- Global regulatory approval in food and pharma

- 5-year shelf life

- No additives such as silica

Physical and Chemicals Characteristics

Solution Characteristics

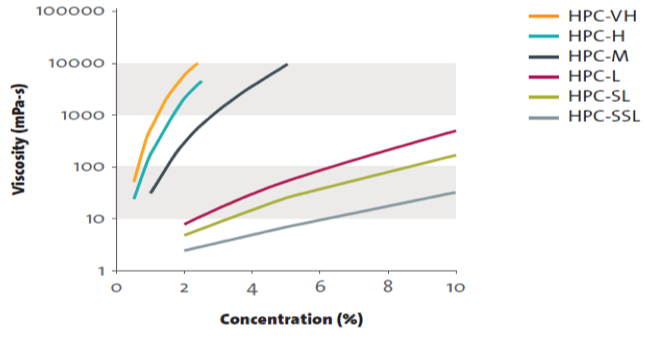

Viscosity vs. Solution Concentration (aq.)

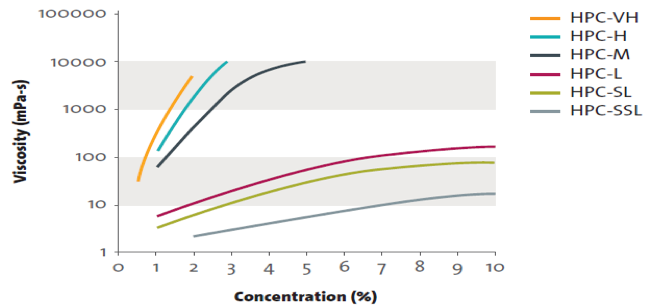

Viscosity vs. Solution Concentration (ethanol)

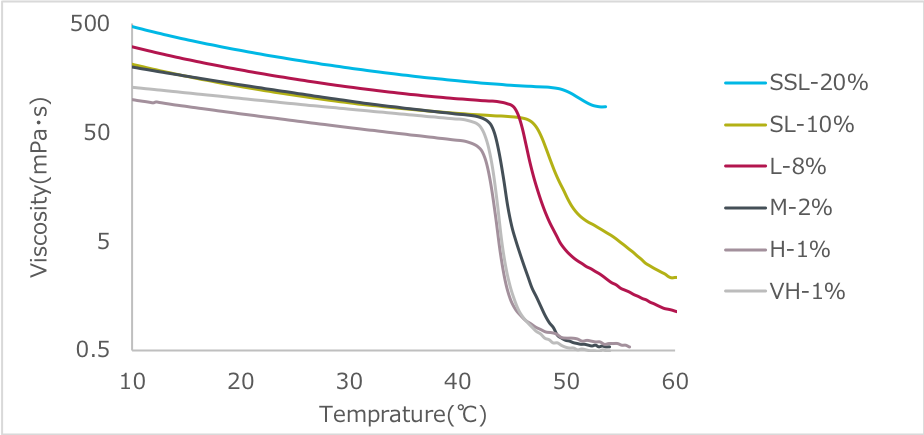

Viscosity vs Temperature Curve

| Gelation Temperature | SSL-20% | SL-10% | L-8% | M-2% | H-1% | VH-1% | Temp.(℃) | 50 | 47 | 45 | 42 | 41 | 41 |

|---|

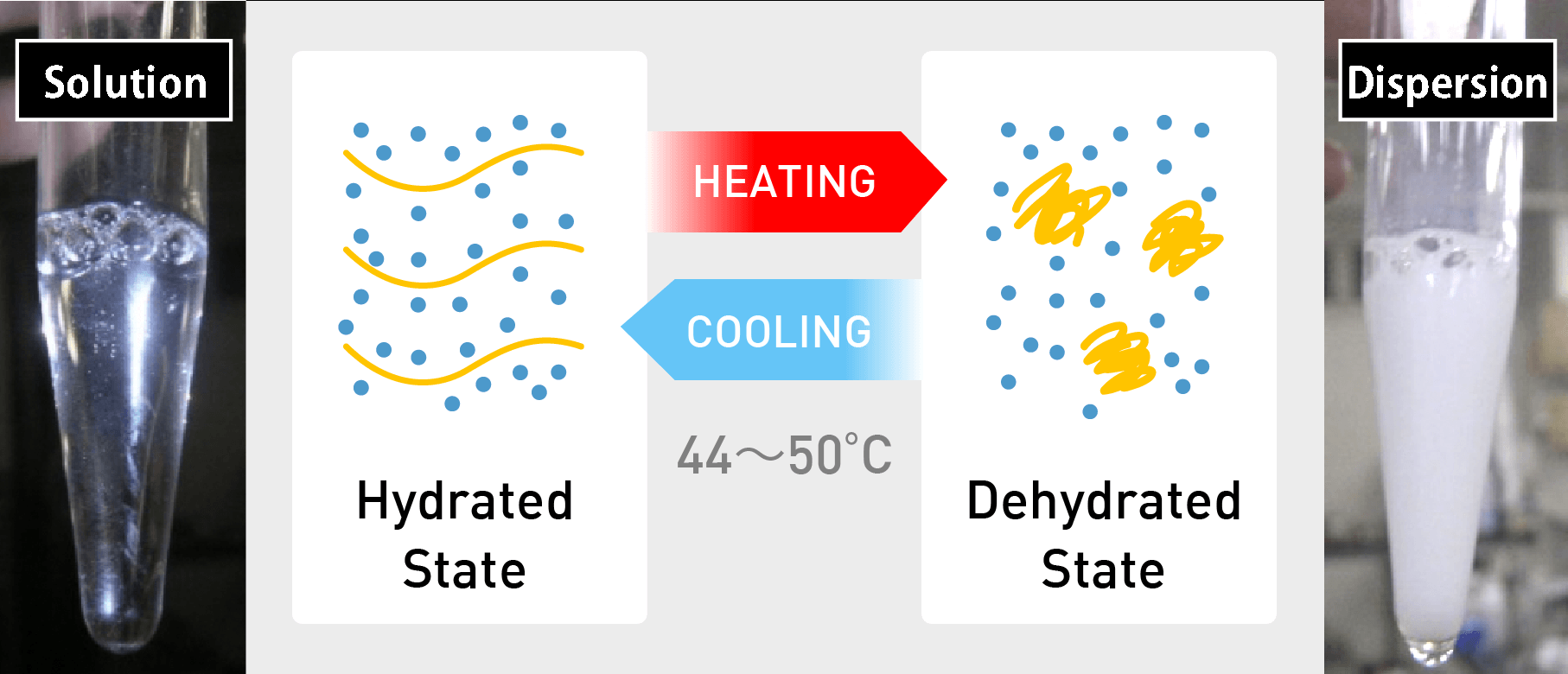

Thermal Cohesiveness

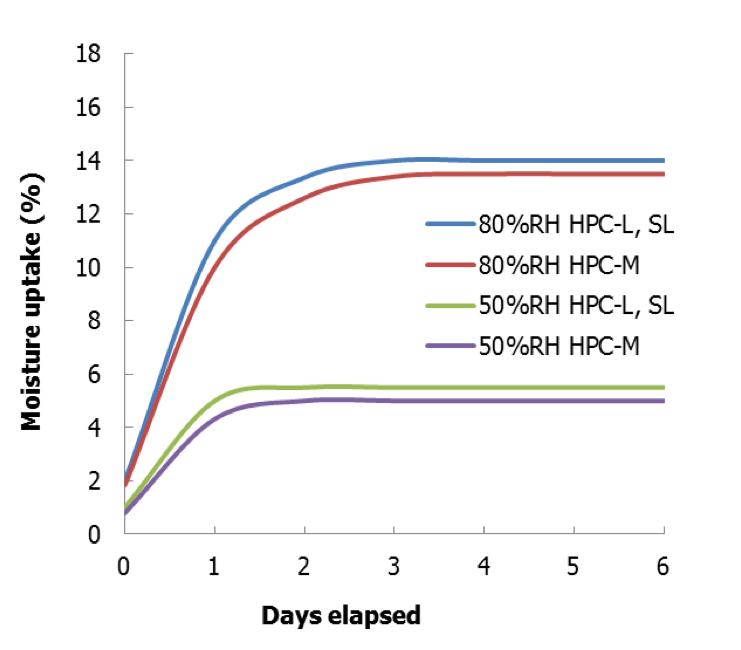

Moisture content over time

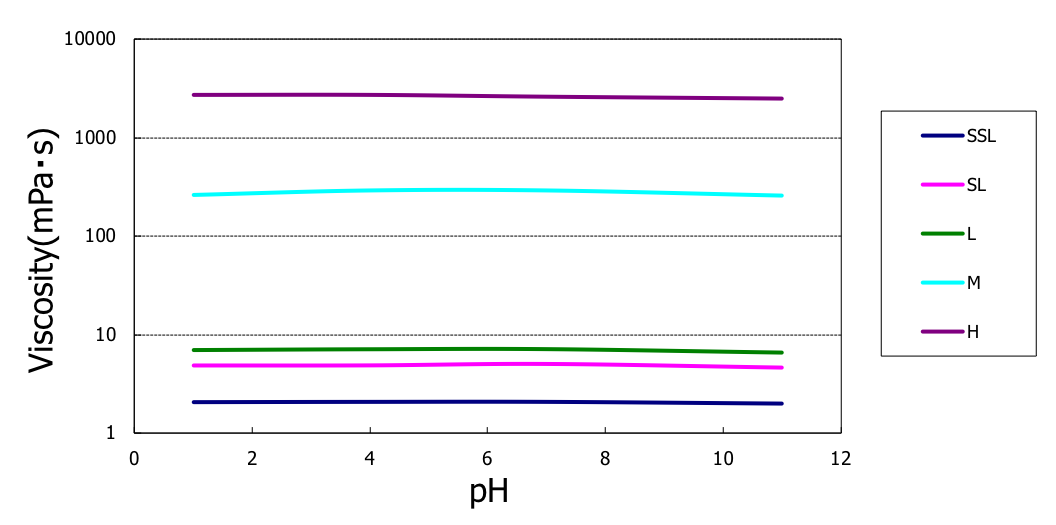

Effect of pH on HPC aqueous viscosity

2% solutions of HPC were measured at various pH at 20°C.

CELNY GRADES & APPLICATIONS

| NISSO HPC | SSL | SL | L | LM | LMM | M | H | VH | |

|---|---|---|---|---|---|---|---|---|---|

| Viscosity (mPa·s) 20℃/2% aq. solution |

2.0-2.9 | 3.0-5.9 | 6.0-10.0 | 11-20 | 21-50 | 150-400 | 1000-4000 | 4001-6000 | |

| Molecular Weight/GPC Method | 40,000 | 100,000 | 140,000 | 180,000 | 280,000 | 700,000 | 1,000,000 | 2,500,000 | |

| AVAILABILITY | Regular Powder (40 mesh pass) D50: 150-190 μm |

* * |

|

|

|

|

|

|

|

| Fine Powder (100 mesh pass) D50: 80-110 μm |

|

|

|

|

|

||||

| Super Fine Powder (330 mesh pass) D50: 20 μm |

|

||||||||

| APPLICATION |

High Shear Granulation

|

||||||||

Fluidized Bed Granulation

|

|||||||||

| Direct Compression Dry Granulation

|

|||||||||

Hot Melt Processing

|

|||||||||

Film Coating

|

|||||||||

Solubility Enhancement

|

|||||||||

Controlled Release Matrix Tablets

|

|||||||||

- General Information

-

Applications